When you choose LED strip lights for your lighting projects, you may often find different SMD models such as 2835, 3528, 5050, 2110 and COB LED and so on. What do these SMD types stand for? How about the different between SMD and COB? And what are their advantages and disadvantages? This article will give you a comprehensive answer to help you make the most satisfactory decision.

Article Guide

1. What Is LED?

LED is the acronym of Light Emitting Diode, is a kind of solid-state semiconductor device which can directly convert electrical energy into visible light. The heart of the LED is a semiconductor chip, one end of which is attached to a bracket as a negative pole, and the other end is connected to the positive pole of the power supply. The chip consists of two parts, one is P semiconductor, and the other end is N semiconductor. When the two semiconductors are connected, a P-N junction is formed between them. When an electric current acts on the wafer through a wire, electrons are pushed from N to P region, and then emit energy in the form of photons, which is how LED lights glow. The wavelength of light, that is, the color of light, is determined by the material that forms the P-N junction.

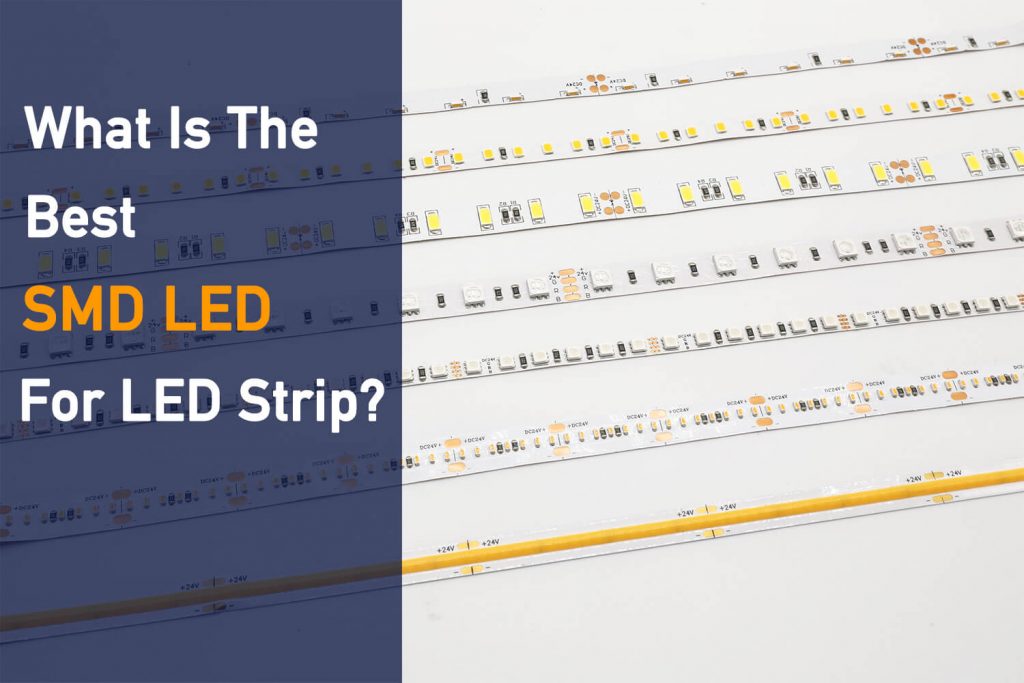

2. What Is SMD LED Strip?

SMD LED, It is a light-emitting diode in Surface Mounted Package.

It is one kind of the use of LED light which can be mounted on PCB or on light strips directly. SMD LED package is basically a plastic casing that houses phosphor and an LED chip. The LED chip, made of semiconductor material, emits light (blue light) while the phosphor material is responsible for converting some of the light into red and green wavelengths. These combinations end up producing the white light that is produced by an LED package.

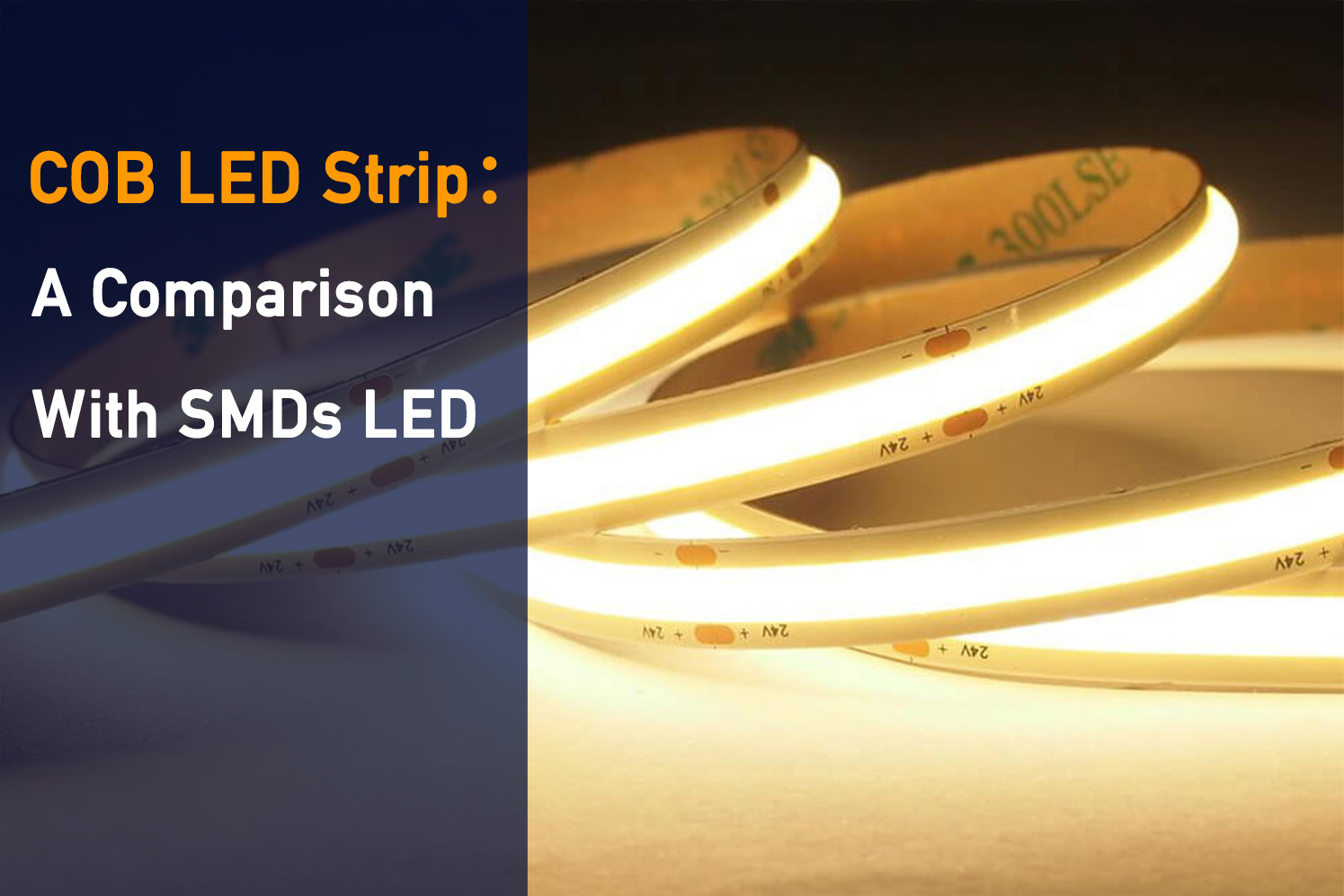

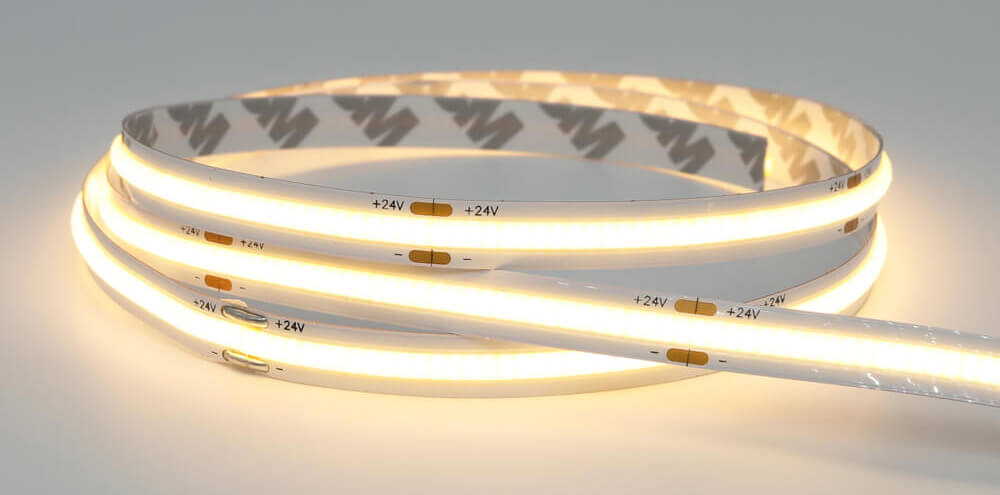

3.What Is COB LED Strip?

COB = Chip On board . COB LED Light can be simply understood as high-power integrated LED light source. In the COB LED process, the placement point of the silicone wafer is first covered with thermal conductive epoxy resin on the substrate surface, then the silicone wafer is directly placed on the substrate surface, heat treated until the silicone wafer is firmly fixed on the substrate, and then the wafer and the substrate are electrically connected by wire welding.

COB light is a high-efficiency integrated surface technology that pastes the LED chip directly on the mirror metal substrate. This technology eliminates the concept of bracket, no electroplating, no reflow soldering, no patch process, so the production process is simpler and the production cost is saved. Because of its non-bracket concept, a higher density LED strip can be designed to achieve the effect of linear light source.

4.What’s the difference between SMD and COB LED?

Let’s take a look at the characteristics of SMD LED and COB LED at first.

- Characteristics of SMD LED:

- Small size. SMD LED is basically a very small chip encapsulated in epoxy, so it is very small, very light.

- Low power consumption. The power consumption of SMD LED is very low. Generally speaking, the operating voltage of SMD is 2-3.6V. The working current is 0.02-0.03A. That is to say, it consumes no more than 0.1W of electricity.

- Long service life. Theoretically, the service life of SMD LED can reach 100000 hours at proper current and voltage.

- High brightness and low consumption. Less thermal radiation than HID or incandescent lamps.

- Environmental protection. SMD LED is made of non-toxic materials, unlike fluorescent lamps containing mercury can cause pollution, while SMD can also be recycled.

- Sturdy and durable. SMD LED is completely encapsulated in epoxy resin and is stronger than light bulbs and fluorescent tubes. There is no loose part in the lamp body, which makes the SMD LED not easy to damage.

- Strong controllability. Can achieve a variety of color changes.

- Features of COB LED light:

- The electrical property is stable, and the circuit design, optical design and heat dissipation design are scientific and reasonable.

- The use of heat sink technology to ensure that COB LED has an industry-leading thermal lumen maintenance rate (95%).

- It is convenient for the secondary optical matching of the products and improves the lighting quality.

- High CRI, uniform luminous, no light spot, healthy and environmental protection.

- However, COB LED light still has some shortcomings, such as optical decay, short life, poor reliability.

Whether it is SMD or COB, each has its own uses, pros and cons. It is not possible to directly determine which one will be more advanced. The difference between them is that SMD is dispersed and more convenient to use flexibly, while COB is integrated, the light source is denser and more linear, but it is not stable at the same time. You should choose the right LED tape light based on the install method and light effect of the project.

5.What is the best SMD LED?

When looking for LED products, you may have stumbled upon 4-digit designations for the LED types. LED package types often have four-digit codes designation such as 3030, 3528, and 5050. The first two digits in the four-digit code represent the width of the package. On the other hand, the last two digits refer to the package’s length, usually in tenths of a millimeter. So for instance, a 3528 LED package has a 3.5mm width and a length of 2.8mm.

In most cases, the larger the package, the more power it can handle. This owes to the fact that it has more surface area to give off heat. However, this is not always the case. For example, the 2835 package boasts of the same surface area dimensions as 3528. However, being a newer package design, it can handle higher power levels. Other factors that contribute to power capacity include the thermal design and the packaging material (e.g. PPA vs PCT vs ceramic).

5.1 Generation 1 SMD LEDs: 3528 SMD and 5050 SMD

When it comes to surface mount style LEDs, the first generation comes in 3528 and 5050 sizes. The 3528 LED has a single 20mA LED chip that is approximately 0.06 watts. The 5050, on the other hand, has three 20 mA LED chips that are approximately 0.2 watts. As such, one 5050 LED package supports a capacity of 3x 3528 LEDs.

The 5050 package not only has a higher capacity, as it has ample space for three different LED chips, it is also a popular way of packaging RGB LEDs that need multiple colors. However, this package can also package single color white LEDs, where three blue LED chips can be used.

There are also some 3528 RGB LEDs, but they only have one color in an LED. This may cause issues to crop up such as color shifts or shadowing because of the uneven spacing. As the RGB LED chips are often found in a single package in a 5050 LED, having a single point source works better.

5.2 Generation 2: 2835 SMD and 5730 SMD

The second generation of LED Packages come with an increase in power density. The 2835 LED is driven at 60mA each, that is, 0.2 watts. The 5730 LED, on the other hand, is driven at 150mA each (0.5 Watts).

Additionally, the power levels in the LED have also increased considerably following improvements in LED chip technology as well as thermal design improvements in the package. Actually, some of the power levels in these LEDs surpass the overall thermal capacity of the whole LED strip system. This is because the thermal dissipation of an LED strip is constrained due to lack of heat sinking or because of the material.

Likewise, the second generation of 5730 and 2835 LEDs offer a lower profile. If you have limited vertical space but have to fit LED strips in the location, this can work to your advantage. Additionally, the package design cuts on issues with fringe yellowing.

5.3 Comparison between the First and Second Generation

2835 LEDs that operate on 20mA can substitute the former 3528 LEDs. In comparison with 3528, they boast of better stability, lower cost, better consistency, and higher efficacy.

The 2835 60mAs are considerably smaller and thinner than 5050s. They are therefore an efficient replacement for the 5050 LEDs as they produce 20 percent more light while having the same power consumption.

The 5730 LED that runs at 150 mA each (0.5 Watts), produces more light compared to the common 5050 or the 2835 SMD. In fact, the high-quality 5730 chips on 60 LED p/m give out around 2000 lumens.

5.4 Other Types of SMD LED

- You might come across the 3014 SMD LED. This LED package is designed to consume low power, that is, approximately 20mA. They are mostly used in LCD backlighting applications that require a high LED count for uniformity. Also, some LED strip light products utilize them in a diagonal pattern and at a high density, so as to come up with a uniform linear light source.

- 3030 SMD LEDs are also utilized on LED strips. A number of these products employ the symmetrical circular light emission surface for they can be coupled with secondary optics and lensing. The 3030 LEDs are designed to operate at 300 mA or above (up to 1.0 Watts). However, following thermal concerns, they are often not run at full capacity when on LED strip products.

- 315 SMD packages are also popular and mostly utilized inside emitting strips. Their working voltage is 12V/24V and are white in color.

- 2110 SMD LED packages is the smallest decorative lighting and is therefore used for high density strips. They are small in size and can accurately achieve a combination of colors.

- 3838 SMD LED type are mostly used in RGB strips. They are utilized in outdoor lighting and decoration lighting.

- 3527 SMD LED packages can be used in RG and BW strips. They can also be used in dual white or dual color strips. They deliver adaptable lighting and can be used to mimic daylight.

- LED packages’ main goal is to boost light output efficiency, device reliability as well as high light color performance. Let’s take a deeper look into these.

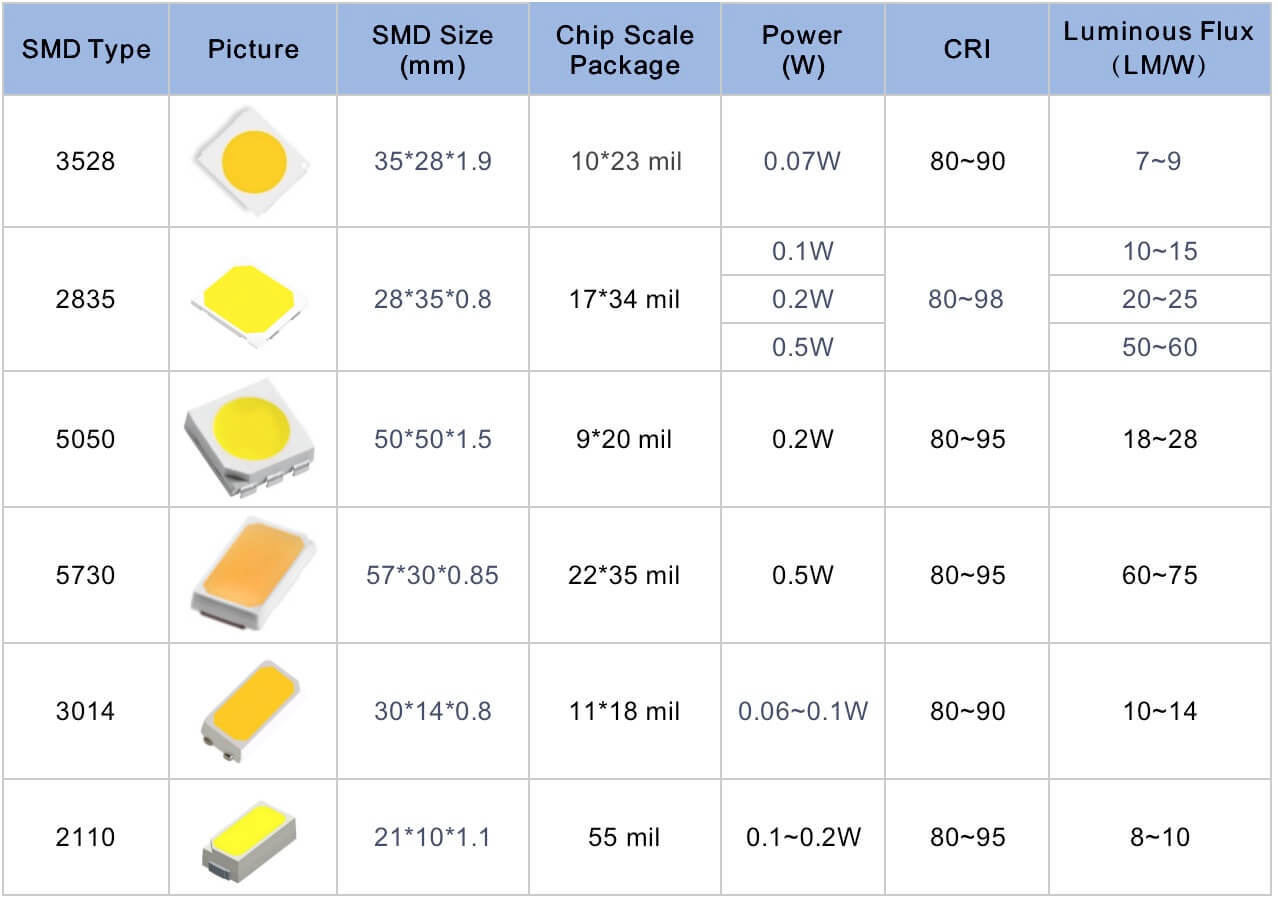

5.5 The comparison table of mainly used SMD LED:

We compare some parameters of several commonly used SMD LED packages for your reference.

6. What factors affect the quality of SMD LED?

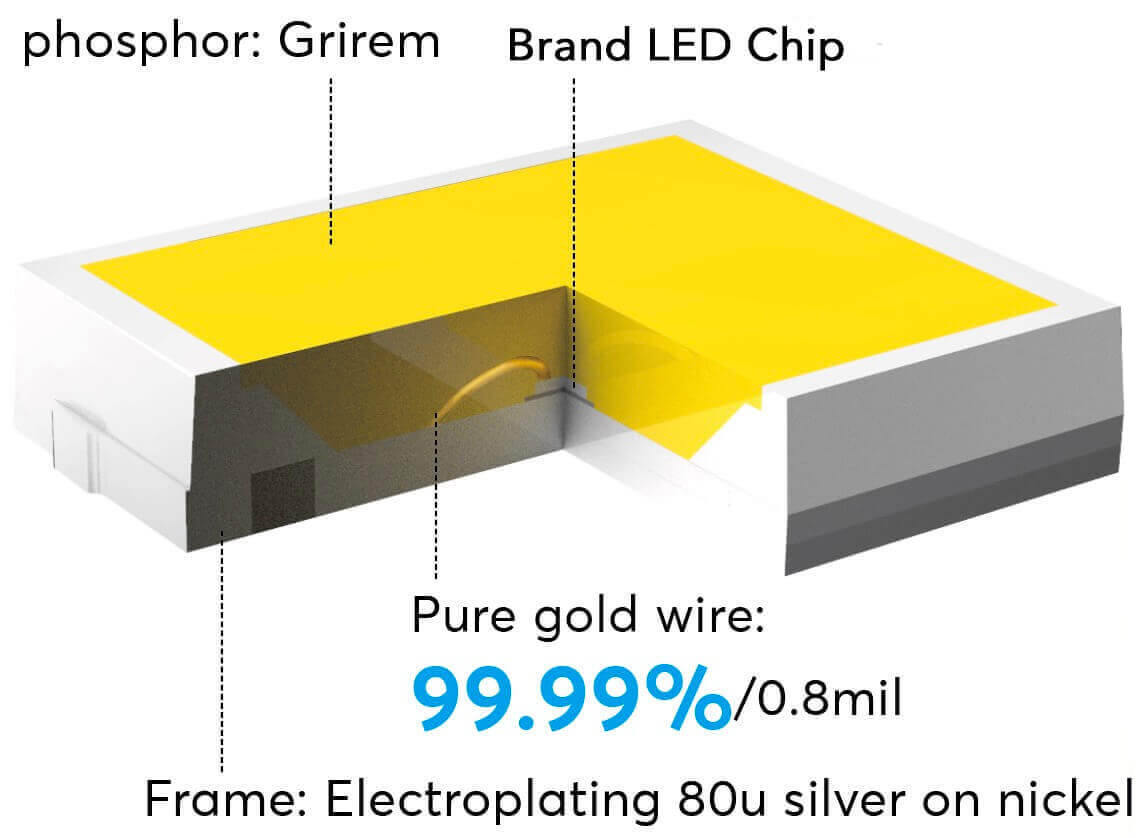

We can analyze the factors that affect the quality of SMD LED from its structure.

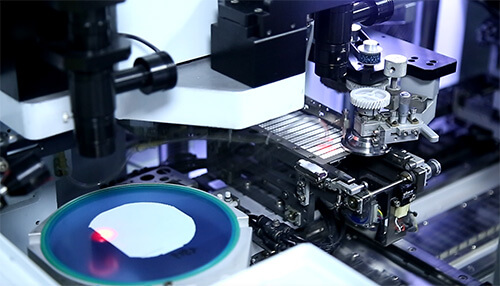

6.1 Chip

The heart of every LED, its chip plays a considerable role in producing good quality LED light. A low-quality chip has less stability. Branded chips such as Epistar, Bridgelux, and Nichia chip are some of the best available chips.

6.2 Lead frame

Another critical factor for high-quality LED is the lead frame. Red Copper frames are more powerful and stable, but they are expensive.

Another critical factor for high-quality LED is the lead frame. Red Copper frames are more powerful and stable, but they are expensive.

6.3 Wire

As mentioned above, the wire bonding process requires excellent quality wires to connect LED die to the lead frame. Wires made of industrial gold are 99.99% pure and result in a better quality of the LED.

In contrast, impure gold or an alloyed gold tends to weaken the wire bonding process, cutting down its quality.

6.4 Phosphor

The LED strip lights undergo phosphor coating during the manufacturing process. American Intematix phosphor adds a protective layer on the LEDs and eliminates UV damage as well. That ensures that your LED lights strips work fine when installed outside. In contrast, a cheap phosphor coating results in a significant drop in the quality of LED lights.

6.5 Professional Testing

- Red Ink Test: to verify the airtightness of SMD LED.

- Cold and Thermal Shock Test: testing the comprehensive performance of SMD LED.

- Salt Spray Test: testing the corrosion resistance of SMD LED.

- High Temperature Thermal Cycle Test: testing the anti-aging performance of SMD LED package.

- IES LM80 Test:It is the optical flux maintenance rate (LED lifetime) standard, which mainly tests the luminous flux output maintenance rate of SMD LED, that is, the lifetime test of LED light source.

In addition, the production environment of the dust-free workshop, advanced production equipment and experienced technicians will have a certain impact on the quality of SMD products. Choosing a professional and experienced manufacturer can better ensure the lighting quality and product stability of SMD LED.

Conclusion:

With the fast innovation of LED technology and more and more extreme lighting demand, new cost-effective SMD LED will continue to be developed. Combined with the characteristics and requirements of the lighting project, the LED strip light with stable quality, high color consistency and high cost-effective will be the best choice.