excellent color Consistency

We beyond the industry standard

In LED light or flexible LED strips, color consistency defines the light quality index. The CCT is the indicator that shows white light as neutral, warm glow as reddish, and cool light as bluish.

On most occasions, the same CCT value can recognize different versions. Therefore, LED manufacturers are designing different techniques to ensure color consistency by strictly controlling color variations.

To achieve the best possible color consistency, Myledy deploy advanced binning selection formulas optimization process to tighten the control on color variations. And you’ll find these formulas exceeding the chromaticity standards set by the industry. That’s to ensure consistency and uniformity of color temperature and hue.

- CCT – Correlated Color Temperature

- Allowable CCT Variations

- Why is Color Consistency Important?

- How Color Consistency Issues Become Apparent?

- What's MacAdam ellipses?

- the Difference in the MacAdam Steps

What's CCT?

CCT – Correlated Color Temperature

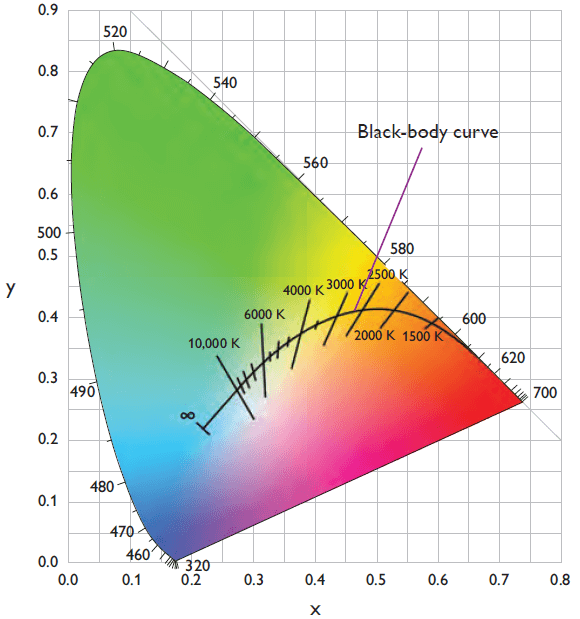

The temperature in CCT refers to the black-body radiation. This is actually the emitted light by a solid object heated to the point of incandescence. The emitted light by a black body as it gets hotter progresses through a particular sequence of colors that follows a curve within a color space. Starting from red, the light passes to orange, yellow, white and blue.

When you keep increasing the heat, the black body emits light that progresses through a specific color sequence. It follows a curve within the same color space.

Now, CCT or Correlated Color Temperature is the temperature of that body when you heat it so much that it reaches the incandescent point. Kelvin is the standard unit to express CCT value.

Can you distinguish those colors with a naked eye? That is where MacAdam’s vision research comes in.

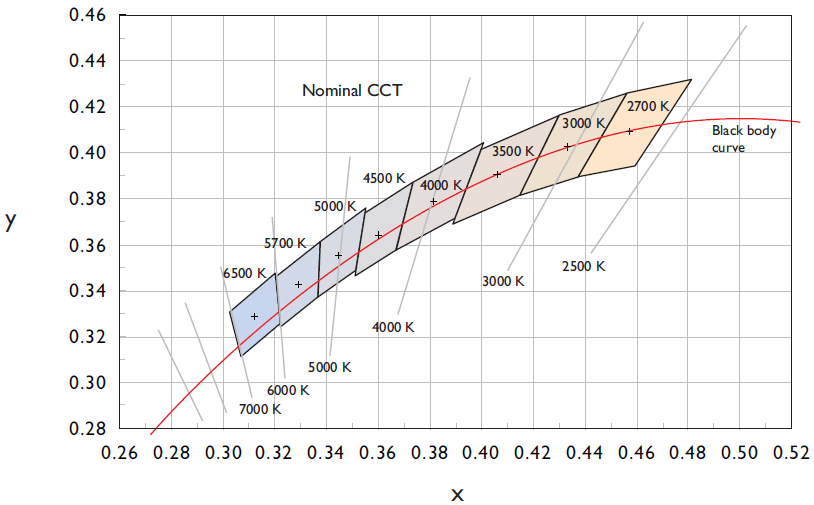

There are several standards defining the various light sources’ chromaticity. For example, for LED sources there are 8 nominal CCTs that range from 6500 K (daylight white) to 2700 K (warm white). Among these CCTs, six correspond to the compact fluorescent lamps’ chromaticity specifications, in order to ensure some consistency across various types of light sources. Another two additional CCTs have been defined in order to cover the gaps not accounted for by the CFL chromaticity standard along the curve, since LEDs can produce any variation of the color temperature within the range.

Allowable CCT Variations

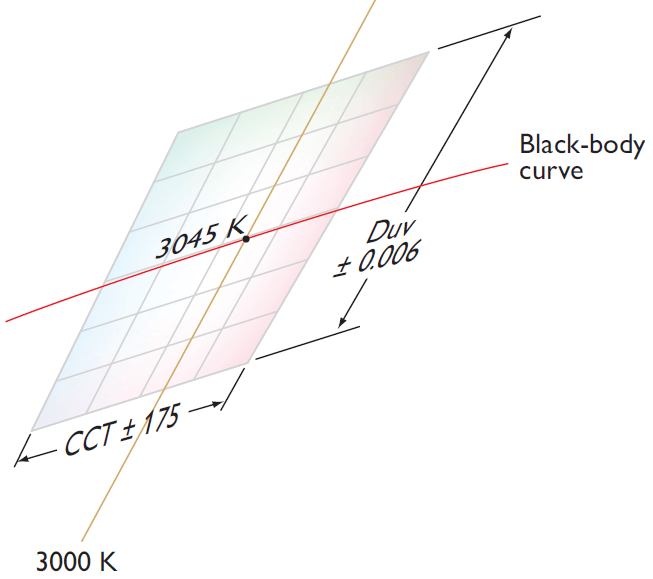

An allowable range of tolerance or variation corresponds to each nominal CCT, both perpendicular to the curve and along the curve. Variations along the curve cause the light source to look more bluish or reddish, while those variations that are above and below the black-body curve cause the light to look more pinkish or greenish. These variations along the black body curve are measured in degrees Kelvin, while variations perpendicular to the curve are notated as Duv.

Within each color temperature’s color space, the allowable CCT variations both perpendicular and along to the curve define a quadrangle. The Duv and CCT ranges for the temperature of each color determine each quadrangle’s size.

For instance, the nominal CCT of 3000 K’s quadrangle has a tolerated variance of plus or minus 175 K, being centered on 3045 K. The 3000 K quadrangle covers along the black- body curve from 2870 K to 3220 K. In practice, even if the measured Duv and CCT of LEDs can vary considerably, the values are still considered to have a nominal 3000 K CCT.

Color Consistency

For white LED lights, color consistency can be a critical but often overlooked quality that can make or break a project. How and why color variation exists? And how to ensure you can attain excellent color consistency for your LED light project? Below content will give you the answer!

Why is Color Consistency Important in LED Strip Lights?

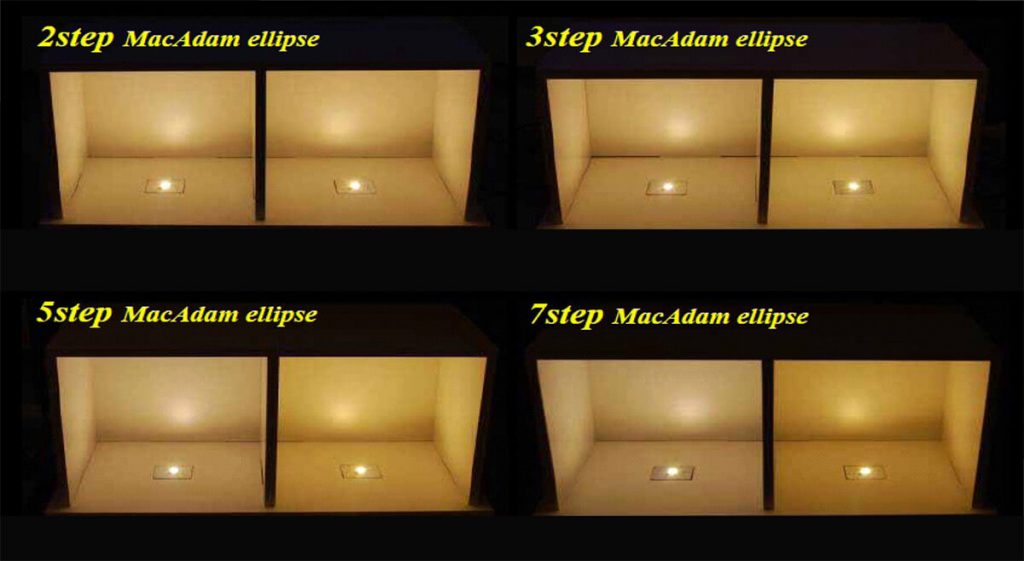

Good quality LED strip lighting with accurate color consistency is essential for the medical, commercial, and industrial sectors. Many manufacturers used SDCM or MacAdam step as the metric unit for color consistency. The larger the number of steps ultimately results in more significant variation in color.

Mostly for standard applications, color consistency is accepted within the 5-step SDCM range. However, for more demanding applications like architectural or professional usage, a 3-step SDCM range is preferably used.

It is essential to ensure color consistency among LED fixtures purchased for multi-site installation. It is also vital for phased installation and for over the time expansion in fixtures.

How Color Consistency Issues Become Apparent?

There are two types of color consistency problems that arise in LED lights:

- within a single LED strip light segment, a color variation is observed.

If there’s too much variation among the individual LEDs on a single tape, it’s the first type of inconsistency. This inconsistency tends to happen when manufacturers conduct preliminary tests done to determine the right level of tolerance. - A color mismatch is observed between LED strip in different batches.

Color mismatch between different batches of LED ribbons is the most apparent and common inconsistency in LED light strips. The primary cause of this inconsistency is the variations occurring between manufacturers or batches.

If there’s too much variation among the individual LEDs on a single tape, it’s the first type of inconsistency. This inconsistency tends to happen when manufacturers conduct preliminary tests done to determine the right level of tolerance.

A color mismatch between different batches of LED ribbons is the most apparent and common inconsistency in LED light strips. The primary cause of this inconsistency is the variations occurring between manufacturers or batches.

MacAdam Ellipse

What's MacAdam ellipse?

You can quickly tell whether the room’s light is too bright or dull and your eyes can also spot the color of light an LED is emitting. How do LED manufacturers maintain color consistency? You should know about MacAdam Ellipse.

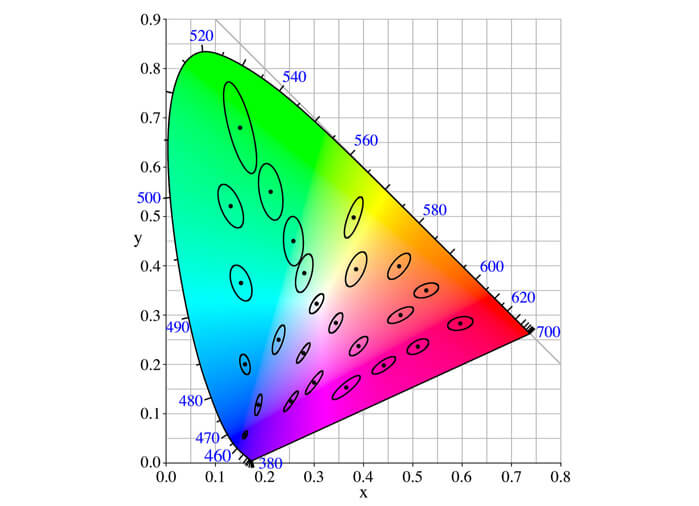

In 1942, David MacAdam conducted a series of tests. Using a graph on CIE 1931 XY chromaticity diagram, he explained that a human eye could distinguish or can’t distinguish changes in color depending upon the color it’s trying to match.

A point on the graph indicates a single color, and each point has an ellipse (of different sizes) around it. According to MacAdam, there would be no visible difference in color within the ellipse from the center point, but chromaticity will differ noticeably as we move to its edge.

The human eye is sensitive enough to detect even the smallest of changes in color. That means it’s crucial to maintain the Color Consistency in CCT. For example, if an LED at 3000k gives a white light, a human eye can spot the color difference with a slight deviation of 60k.

To get more precision and accuracy, MacAdam’s steps helped a great deal in refining the binning process of LED colors. MacAdam Ellipse measure even a small color variation in LED light appearance.

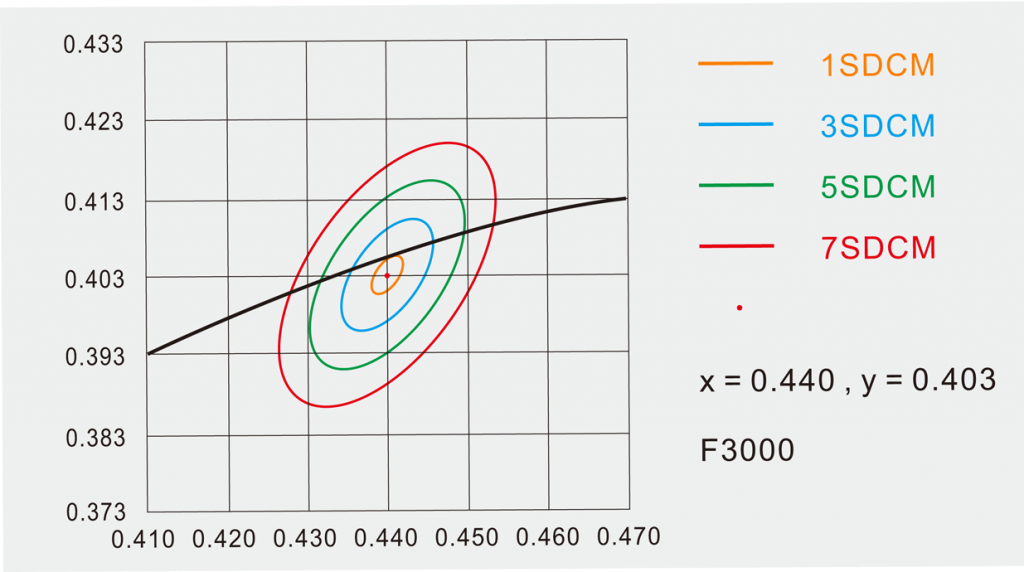

MacAdam Ellipse or MacAdam Step is also known as SDCM(Standard Deviation Color Matching), both of which refer to the same concept and metric. One MacAdam Ellipse represents some specific zones in the CIE 1931 XY color space which the human eye cannot differentiate visible colors within these zones.

MacAdam Ellipse (SDCM) is a superior metric compared to CCT and Duv for two reasons:

- First, it captures the variation in both the blue/yellow direction and green/magenta direction and distills it into a single number. This can be useful because in some cases the color inconsistency can occur in both dimensions.

- The second reason is that a 100K color difference is considered larger at lower color temperatures. SDCM algorithmically takes this into account and makes the necessary adjustments depending on the color temperature. The primary disadvantage is that many manufacturers are not sufficiently concerned about color difference and will oftentimes be unfamiliar with this metric.

the Difference in the MacAdam Steps

Normally, lighting manufacturers will describe their color consistency using a metric called SDCM or MacAdam ellipses, The unit of measure is a “step” and the larger the number of steps, the larger the variation in color.

LEDs are mostly binned at the 1-7 step level, which means that they all have the same CCT; however, there is certainly a color difference in one bin of LEDs.

Due to the variability of colors produced LED the manufacturing, the MacAdam ellipses are a handy measuring tool to define color dispersion between bins. In general, the market accepts color consistency of 5-7 SDCM with slight visible differences. 2-3 step SDCM range for more demanding applications for professional or architectural uses. MacAdams Ellipses inferior to the 3-steps (3 SDCM) which is hard to see the visible difference offer better Color Consistency for LED strip lights.

How does MyLedy Control the color Consistency?

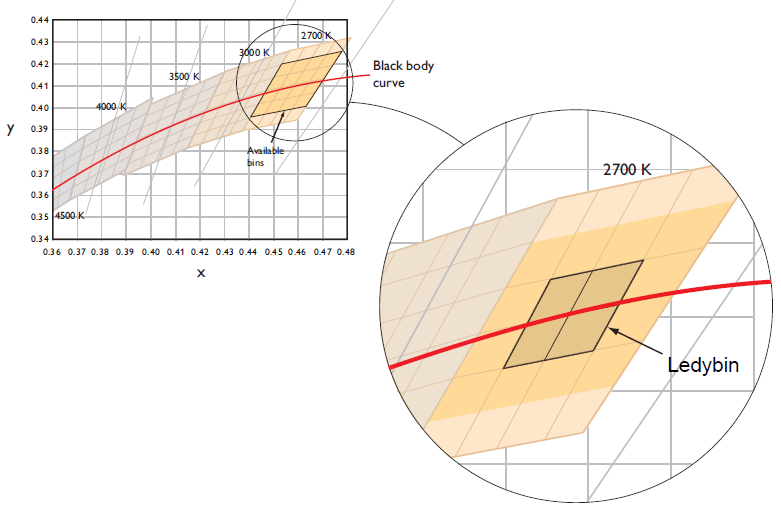

1. Ledybin

LEDs with perfect color consistency depend on the process of LED sorting in the Manufacture of Light Emitting Diode Package. This step makes Binning for the LEDs. The packaged LEDs can be tested and sorted according to wavelength, luminous intensity, light-emitting angle, and operating voltage. As a result, the LED is divided into a plurality of bins and categories. Then the test sorting opportunity automatically divides the LED into different bins according to the set test standards. LED testing and sorting is an essential step in the LED manufacturing process.

As leading LED strip light manufacturer, Myledsy aim to ensure color consistency by developing methods to strictly control color variations, and employ advanced binning selection formulas that exceed chromaticity coordinates industry standards in order to guarantee consistency and uniformity of color temperature and hue.

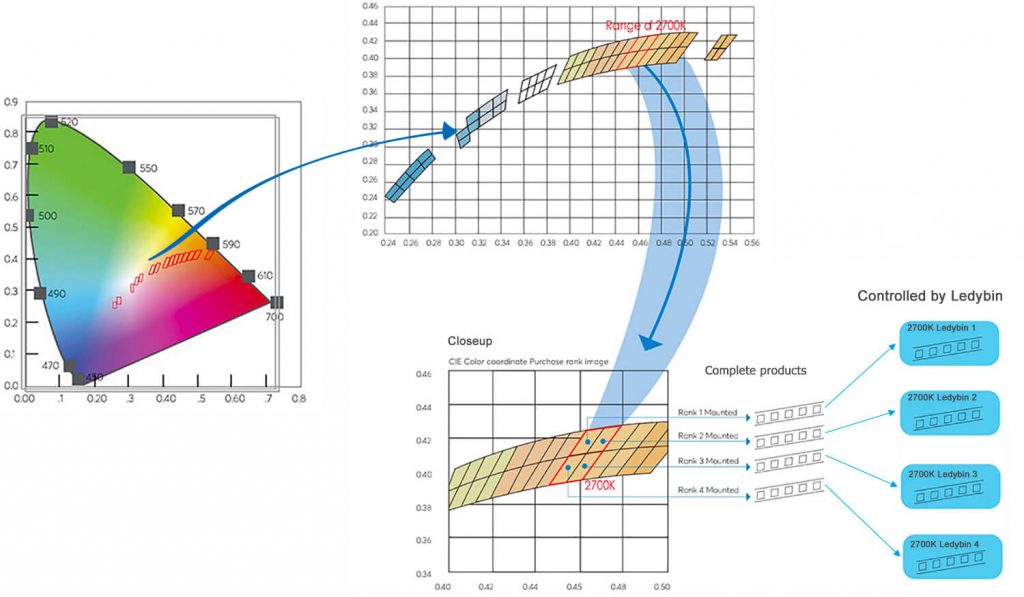

Myledy has developed a mathematical classification model, called Ledybin. Across all LEDs production, this mathematical model guarantees the color uniformity for all LED ribbons.

The Ledybins CCT and the hue tolerance of LED ribbons follow the 3-step MacAdam ellipse, instead of the 7-step ellipse of ANSI standards. The bins containing LEDs within the 3-step ellipse are chosen by Ledybin. That ensures perfect color consistency.

Usually, there are four bins within a five-step MacAdam ellipse. However, we will use only one bin for different manufacturing runs to ensure 3 SDCM consistency for your strip lights order. Additionally, Ledybin algorithms also ensure consistency in led strip lights from reel to reel and batch to batch.

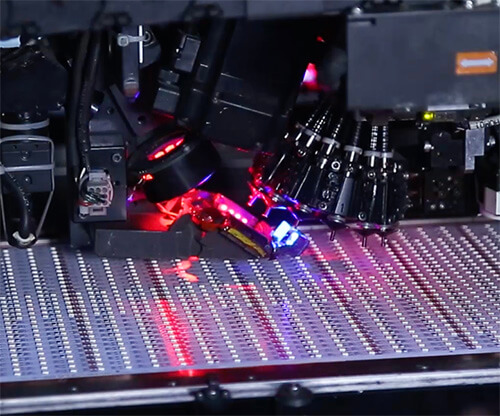

2. Myledy Color temperatue control

Light color consistency is an key important indicator of LED strip quality, while the quality of LED source is determined by LED components. Every process with strict control is vital importance for LED components manufacturing, such as ratio control of phosphors, glue dispensing, sorting, SMT and testing.

Ledybin Standard

<3 Steps MacAdam ±50K

Customized colors are available, Myledy has our own LED packaging facilities, that’s very important to achieve high standard color consistency.

The color temperatures of some of the products sold by LEDMY are beyond the industry standard to meet the needs of our customers. LEDMY original rules have been set for these.

Only single Ledybin in the LED packages would be selected to customer’s every and each order. For all the LEDs, there would be additional visual inspection after the selection of machine. All the orders would have both documents record and actual LED samples for comparison.

3. Myledy Color Consistency Inspection

In order to make sure non-defective passing to our customers, Myledy always inspects and compares of color consistency strictly, the main steps as below:

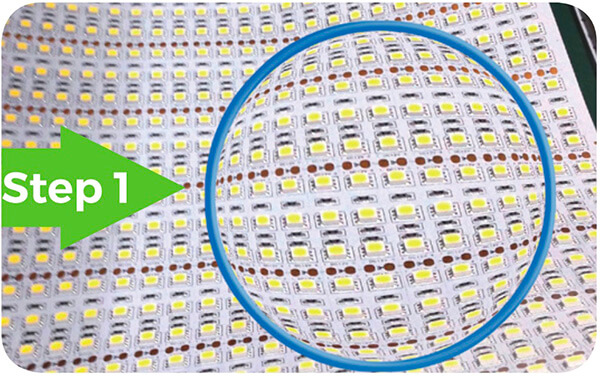

LED Surface Checking

First, inspect the appearance of the LED chip, make sure LED surface is clean, no stains and spots, no short bridging in soldering.

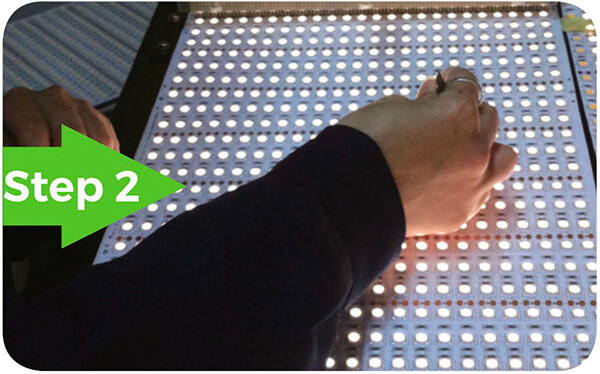

Mark Defective LED

Second, laying the finished product on the testing shelf, turn on lights to mark the defective such as dead LEDs, open soldering, glue crack and excessive brightness.

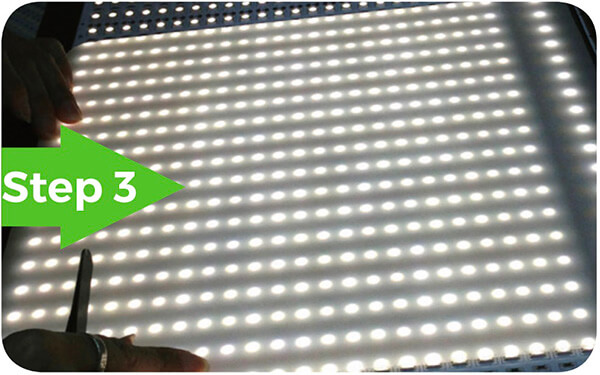

Check Color Consistency

Third, cover led source with PMMA board, observe the color of the finished products and compare color with the first piece sample to ensure the color consistency. Meanwhile, mark the defective products with labels.

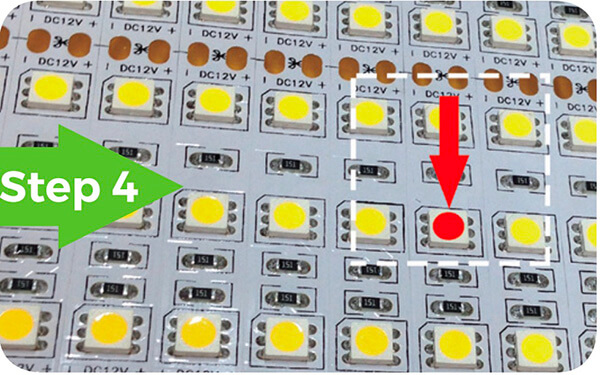

Return Defective LED

Fourth, defective products will be returned for analysis and repairing.