Quality Control of LED Strip Lights

We create the Quality standard

LED lights have been popular in lighting markets for several years, you can find many LED strip lights in Amazon, Alibaba, etc. You must wonder why most of the LED Strips look the same but the prices vary considerably? What affects the quality and life span of the LED tapes?

This article will take MYLEDY’s LED light as an example to analyze fully the internal structure of LED lights, and show you why does MYLEDY’ LEDs make the highest quality LED Strip light.

myledy quality control system

- 1. integrating sphere test for LED

- 2. color comparison checking

- 3. lighting source test

- 4. environmental test

- 5. corrosion resistance test

- 6. waterproof test

- 7. integrating sphere test for LED tape

- 8. carton box drop test

The best LED Strip light

Now that you know how LED tape lights are manufactured. Next we will take you to learn more about the internal structure of LED strip and the factors which will affect its quality:

1. Structure of LED Package

Most of the time, the reason behind an LED that emits low-quality light is faulty or cheap components used in it.

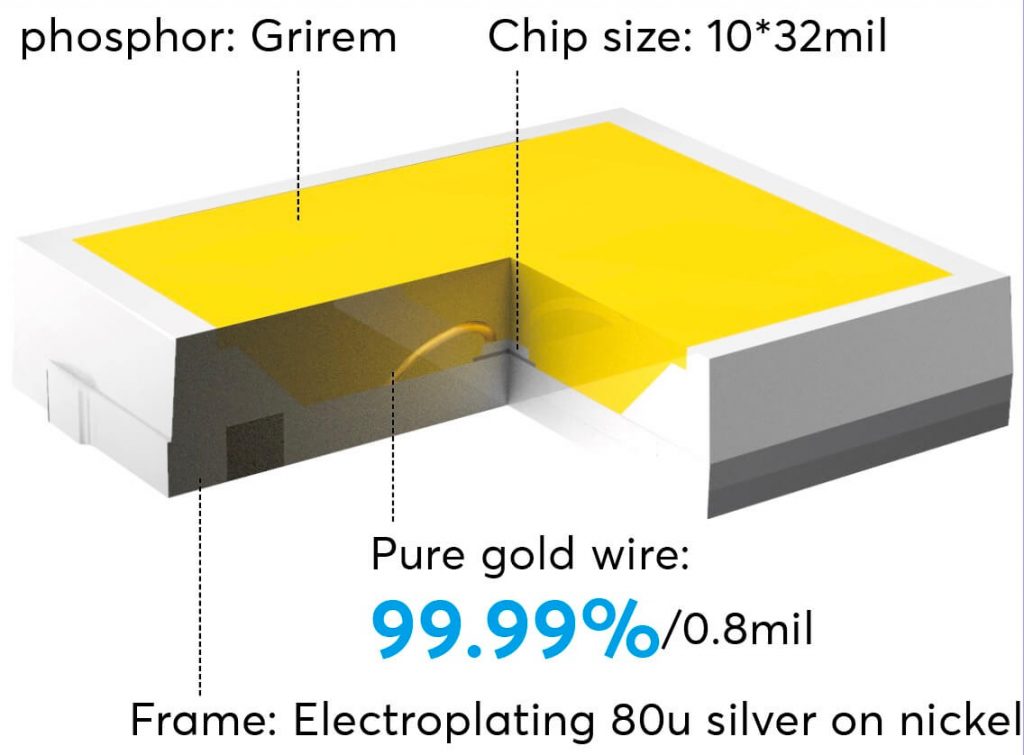

1.1 Chip

The heart of every LED, its chip plays a considerable role in producing good quality LED light. A low-quality chip has less stability.

Branded chips such as Epistar, Bridgelux, and Nichia chip are some of the best available chips.

1.3 Wire

As mentioned above, the wire bonding process requires excellent quality wires to connect LED die to the lead frame. Wires made of industrial gold are 99.99% pure and result in a better quality of the LED.

In contrast, impure gold or an alloyed gold tends to weaken the wire bonding process, cutting down its quality.

1.2 Lead frame

Another critical factor for high-quality LED is the lead frame. Red Copper frames are more powerful and stable, but they are expensive.

Another critical factor for high-quality LED is the lead frame. Red Copper frames are more powerful and stable, but they are expensive.

1.4 Phosphor

The LED strip lights undergo phosphor coating during the manufacturing process. American Intematix phosphor adds a protective layer on the LEDs and eliminates UV damage as well. That ensures that your LED lights strips work fine when installed outside.

In contrast, a cheap phosphor coating results in a significant drop in the quality of LED lights.

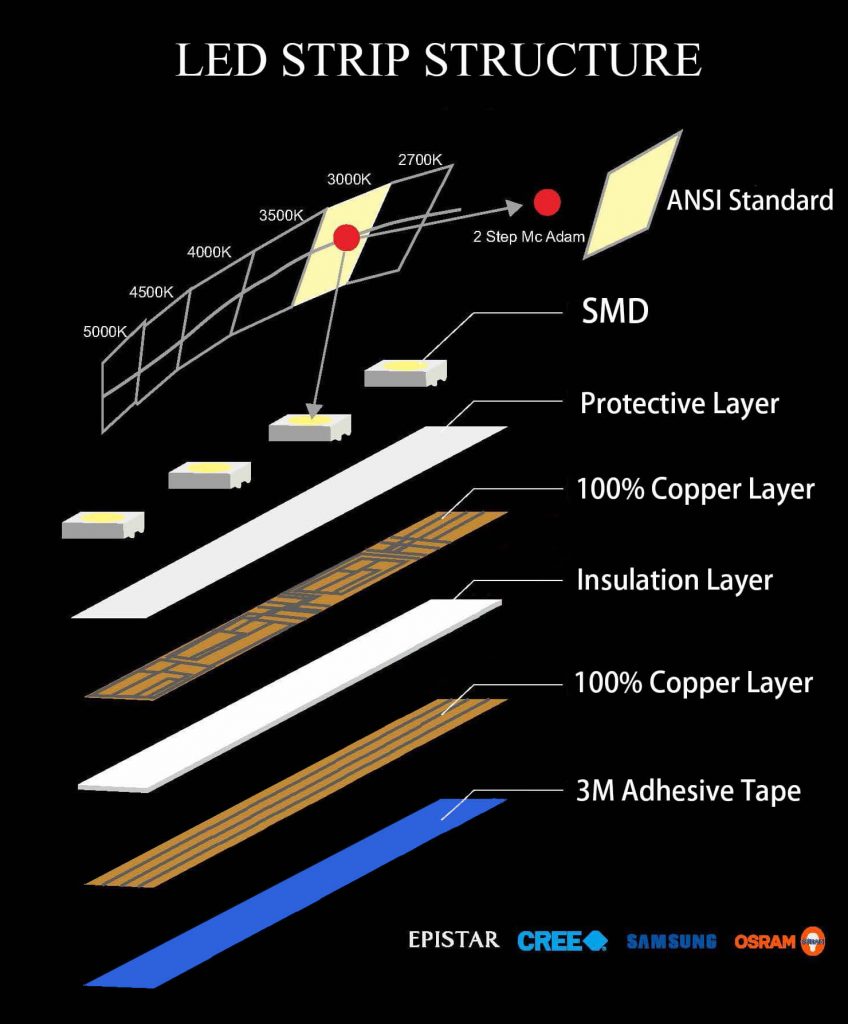

2. Printed Circuit Boards

Just like the components of LED, printed circuit boards used in the end product are also important. For high power LED strips, Myledy always uses Double-layer PCBs of 2.0 ounces.

These PCBs use two layers on both sides of the substrate. On one side, they have one substrate layer and then a conductive metal layer on both sides of the substrate.

Here are some advantages of using thicker copper:

2.1 Flow of Electricity

It allows a better flow of electricity throughout the LED circuit. Usage of insufficient copper creates resistance, thereby leading to excessive heat build-up. It reduces the life of an LED due to sudden voltage drops.

2.2 Faster Heat Diffusion

Having thick copper in the PCB, results in faster heat diffusion. Copper conducts heat well, so it can result in a better heat dissipation process. It improves the life of an LED strip light as well.

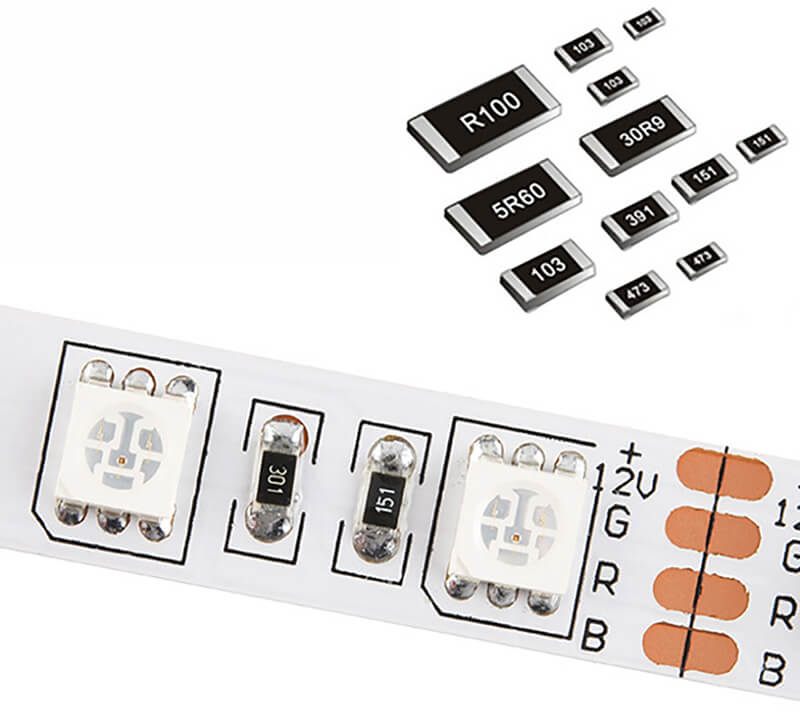

3. Resistors

A resistor prevents LED light from excessive current to pass through it and stops the LED light from burning. Cheap LED strip lights use small resistors, ineffective in protecting the strip light from burning down.

A suitable resistor stabilizes high or very low current before passing it forward to the LED light, ensuring LED’s protection and longer life.

4. Waterproofing material

A good-quality LED strip will always use silicone glue as a waterproofing material. Silicon glue is odor-free, and its color doesn’t change after a long period. It works fine in harsh temperatures ranging from -50 to 300 degrees.

The silicon glue also protects your LED strip lights from corrosion, discoloration, and corruption. In contrast, other waterproofing materials include PU glue and epoxy resins. These materials are prone to wear and tear. After prolonged usage, they begin to swell and turn yellow.

5. Aging test

Last but not least is the aging test every high-quality LED strip has to pass through. An aging test validates the strength of an LED and ensures consumers get the best product.

An exceptional LED strip typically withstands 4-8 hours of an aging test. In comparison, a poor-quality LED strip doesn’t undergo any aging test at all.

5. Certificates

Certificates are not only the basic guarantee of any a product, also the pass cards to large markets.

And now, Myledy has won the title of National High-tech Enterprise, and passed the ISO9001 quality system certification and ISO14001 environmental system certification; all products have passed the test of third-party authoritative laboratory institutions and obtained quality certifications in various countries and regions: CE, REACH, ROHS, UL, ETL , SAA, TUV, LM-80, etc.

Conclusion

LED strip lights go through a rigorous manufacturing process, and after several thorough testing procedures, the end consumer can finally get the best quality led strip lights. Before the purchasing, make sure LED strips’ components are of high quality.

We hope this article answers your queries regarding the manufacturing process of LED strip lights and helps you choose the best LED strip light for your lighting projects.

An exceptional LED strip typically withstands 4-8 hours of an aging test. In comparison, a poor-quality LED strip doesn’t undergo any aging test at all.