How to Order Customized Strip From Myledy?

We start from your point of thought

Are you looking for ways to decorate your high-class lighting project with led strip lights, but can’t find the perfect one? Then you are in the right place. Because at Myledy, we give our consumers a chance to order customized strips.

Established in 2003, Shenzhen Myledy Co., Ltd., is a leading manufacturer of high-quality LED tape lights. We began our journey by learning from world-famous brands such as Samsung, Epistar, and Bridgelux. Today, we are one of the most renowned independents LED lights producers globally, known for our efficient and long-lasting LED products.

Are you wondering how to order a customized strip from us? Pls keep on reading this guide and learn how we manufacture excellent quality LED lights strips, ensuring our customer’s satisfaction at all levels.

What We Can Do For Your Customized Projects?

Our wide selection of LED strip lights and accessories delivers incredible flexibility, impeccable quality, and unmatched performance. Whether you need a simple set-up or a complex, custom product, we’ll work with you to find the right lighting solution for your project—guaranteed.

Project Review

Before taking up any project, our first and foremost task is to communicate the project’s requirements, goals and results with our clients.

Project Reviews include client’s expectations from us, product quality they desire, and product specifications for their order.

Myledy conducts a thorough project review and clarifies any client concerns beforehand. After the project review, we decide appropriate pricing based on the client’s order size and other requirements.

Get Expert Advice from Myledy

Myledy have a wide range of LED strip lights available in different sizes, lengths, color temperatures, and IP ratings. Whether you are a beginner, designer, or expert, you can get helpful advice from Myledy on LED lights strips. So, our clients can enjoy an excellent customization experience along with superior value LED strip lighting.

Our Engineering, production, and QC teams provide expert advice to our clients at every stage. That helps us foster strong and long-term relationships with our clients.

Guaranteed to Work. Built to Last.

We meticulously use the best components, follow precise manufacturing processes, and perform extensive product testing to ensure that everything we sell delivers consistent performance and a long lifespan—backed by 5 years warranty.

We partner closely with our clients to ensure that every project is a success, offering great tools, services, and resources to help support your vision and your business.

Step 1. Confirm the LED Strip Characteristics

As mentioned above, the client has to confirm the custom features first to begin the project. Following are some custom features we provide for any LED strip lights custom order:

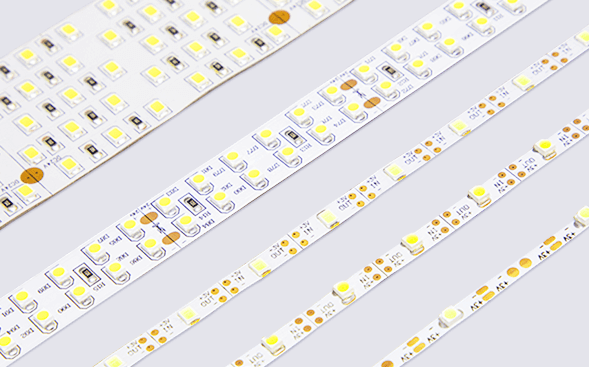

Size of LED Tape

The size means the width of PCB. LED strip lights can make different width to satisfy designers' special requirements, such as super slim lighting, wide addressable design etc.

Myledy provides a vast array of LED tape lights ranging from different widths and lengths. Our LED strip lights are available in widths ranging from 4mm to 58mm for selection:

Logo Printing on Printed Circuit Boards

Myledy allows its users to decide if they want a logo printed on PCBs. And we also print production dates on all PCB back, which will help us track order and minimize the risk of any potential drawback in the future. We provide logo or batch code printing on orders with a minimum quantity of 1000 meters.

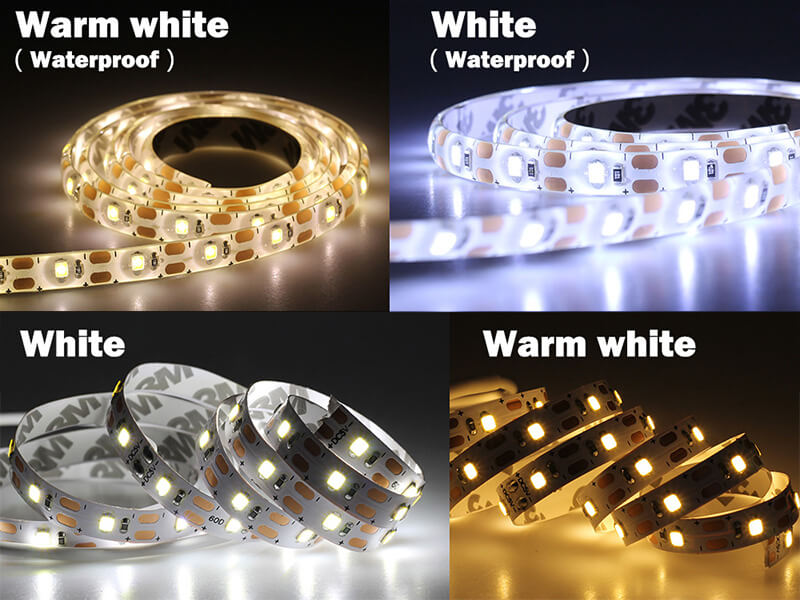

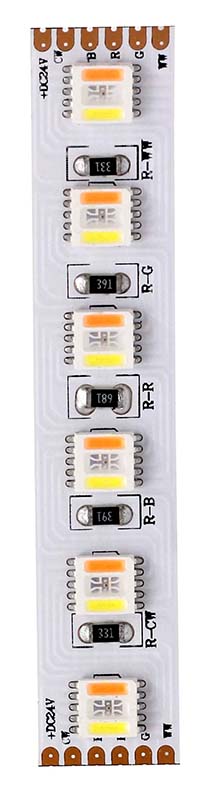

Light Color

The next thing we provide customization for is the LED light color. We manufacture LED strip lights with a wide range of single colors as well as multi-colors. The colors include:

- White color

- Green

- Blue

- Yellow

- Orange

- RGB or RGBW (Multi-color

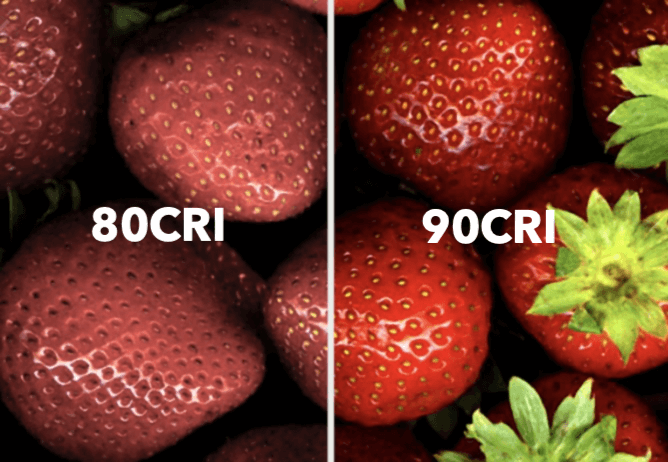

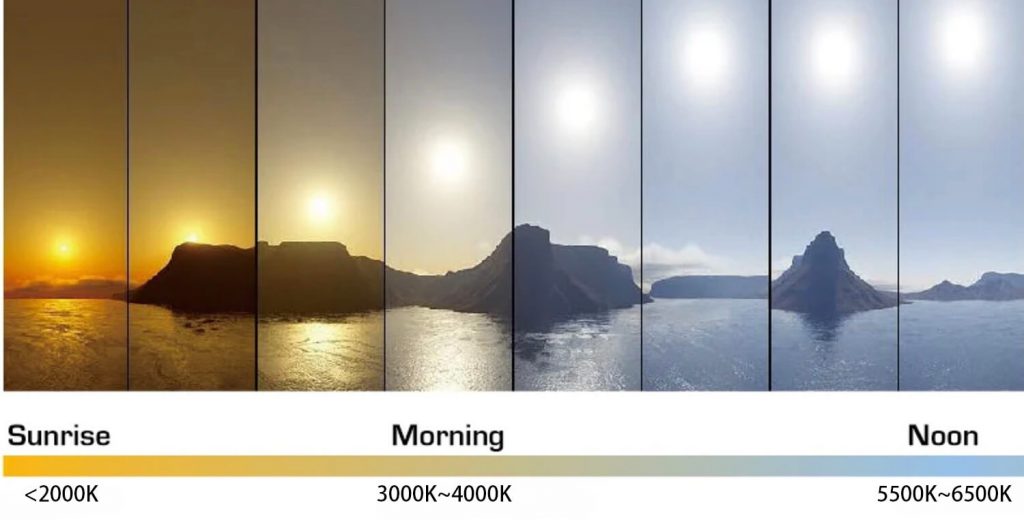

Color Temperature(CCT) and Color Rendering Index(CRI)

The two most important metrics for measuring color’s quality are Color temperature and Color Rendering Index.

measures the accuracy of light’s color under the light source. An LED strip light with low CRI(<90) produces distorted colors. Whereas the high CRI(>90) LED produces high-quality illumination, you can view natural daylight things.

Color Temperature metric measures how warm or cool a light’s color is. Myledy provides color temperatures ranging from 2000K to 6500K. Here are some color temperature ranges we provide:

- 2100-2400K: For soft, relaxing light suitable for a light glow in dining rooms or bedrooms.

- 2700-3000K: This is a comfortable, cozy glowing light that is commonly used for lighting wooden furniture.

- 3000-4000K: This color temperature produces a warm glow in white color for office rooms or kitchens.

- 4000-4500K: For a neutral shade in white color used mostly in offices or schools. This shade is best for reducing eye strain.

- 5000-6500K: Produces a bright white light and works best for areas that require high illumination in commercial displays.

Voltage

There are two types of light strips available in terms of voltage:

- DC12V – LED strips with 12V have a maximum run-length of 5 meters;

- DC24V – 24V LED tapes have run-length ranging from 5m to 10m.

Many consumers face a common issue with DC circuits, that’s the voltage gradually decreases along the strip’s length. This issue leads to a lumen decay at the other end of your strip light. We suggest our customers using 24V LED strips lighting or Constant Current LED tapes.

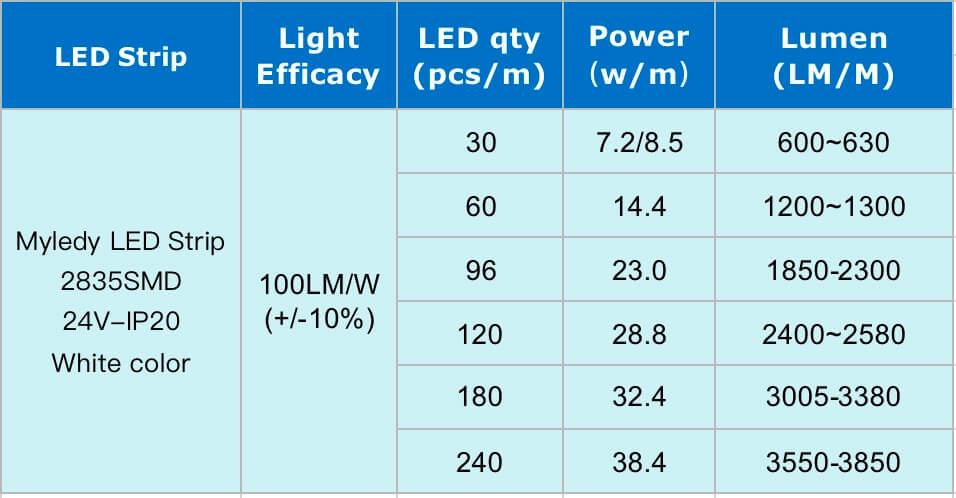

Lumen Output and Wattage

What Is Wattage?

The Wattage of the light is the amount of energy it takes to produce a certain amount of light. The higher the wattage, the brighter the light, but also the more power it uses. With the push for LED lighting, there is others take into consideration for lighting levels. One of the biggest arguments is Wattage versus the Lumens to determine brightness. For incandescent lamps, the higher the wattage the lamp is, the brighter it is; but we focus on the Lumens, when it comes to LEDs light.

What Is Lumens?

Lumen refers to the amount of light emitted by a lamp, which is what we usually call brightness. The reason why LED lamp is so popular is that its high lumen can play a role in environmental protection and energy saving. If you replace a standard 150-watt bulb that emits about 2600 lumens, a 25-watt LED is roughly the same.LED strips’ lumen output level varies depending upon the usage of your strips. Here is Myledy’s wide range of Lumen output per meter:

- 510-1150 lm/m: best for mood or accent lighting

- 570-1700 lm/m: mostly used for cabinet lighting

- 910-1430 lm/m: produces best task lighting which is close to the light source

- 1120-2250 lm/m: best used for task lighting that is away from its light source

- 1230-1840 lm/m: mostly used for indirect lighting in bedrooms or hotels

- 1640-3220 lm/m: for commercial usage or industrial lighting such as signage, linear lighting

IP Rating

LED strips’ lumen output level varies depending upon the usage of your strips. Here is Myledy’s wide range of Lumen output per meter:

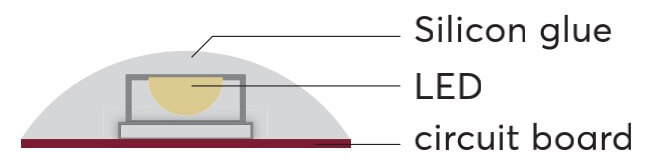

IP20

They are non-waterproof, best for indoor rooms only, such as bedrooms, furniture, cabinets.

IP62

LED strips with IP62 come with silicon glue added on top of the strip. They are suitable for damp areas such as bathrooms and kitchens.

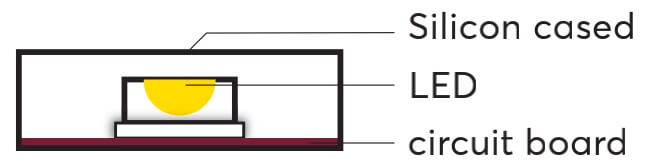

IP65

IP65 strips come with a wrapping protective silicone sleeve. They are best for damp areas or outdoors but aren’t entirely waterproof.

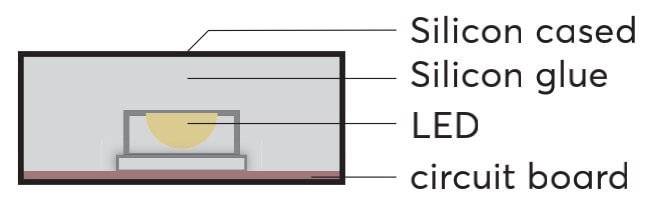

IP68

The IP68 LED strips are sealed with a silicone sleeve strip with silicone glue injection. They are completely waterproof and are for underwater applications such as pools, harbors, or docks.

sept 2. Select Adapted Heat Sink and Diffuser - LED Channel

Heat dissipation is a prevalent phenomenon all LED lights experience. To counter this issue, Myledy produces high-quality LEDs with reliable thermal management.

Furthermore, LED aluminum channel with a diffusion cover is the most common way for heat dissipation, which improves your LED light strip’s lifespan and lighting aesthetics. These aluminum channels primarily facilitate the diffusion and mounting process.

At the same time, a variety of LED Profiles can not only create a variety of modeling designs, but also make the lighting of led strip more smooth and beautiful.

Step 3. Select Adapted Accessories

After deciding the right LED channel, the next stage involves the customization of adapted accessories.

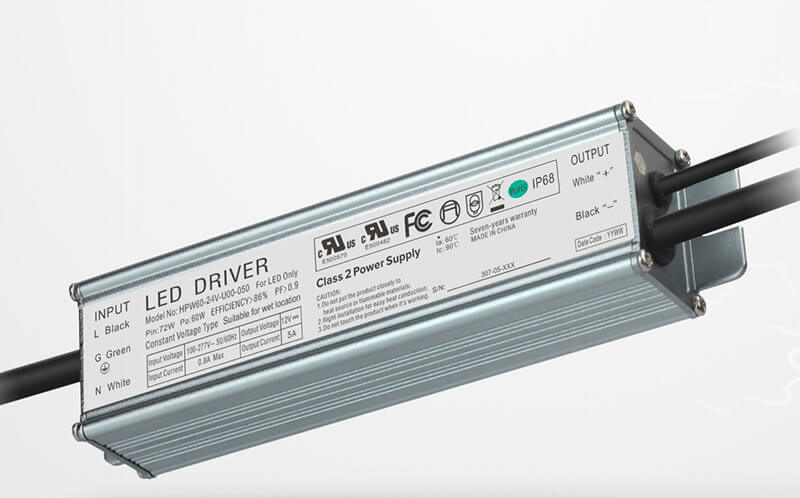

Power Supply

Every LED strip needs an adaptor to DC power supply. Myledy provides its consumers with an optional power supply. Here are some tips for choosing a right adaptor for your LED strip project:

- First, you need to figure out the LED strip voltage and determine whether it is a 12V or 24V DC power supply.

- Next, you should calculate for the wattage and amperage specification on the LED ribbon.

- Lastly, You should confirm what kind of plug the LED strip comes. Depending on that, you can decide on a suitable power supply plug. Just make sure the power supply plug needs to be compatible with your LED strip.

Controller

Every LED strip needs a connection to a DC power supply. Myledy provides its consumers with an optional power supply.

Adapted Wire

We routinely use 20 AWG Solid core wires as adapted wire, but different project designs may require special requirements for connect cable, such as RVV/RVVB wire (dual insulation Cable ) or UL standard cable etc. At Myledy, we give our clients full independence to select wire type and length as per their requirements. So, they enjoy optimum lighting results, and the best quality LED strips lighting experience..

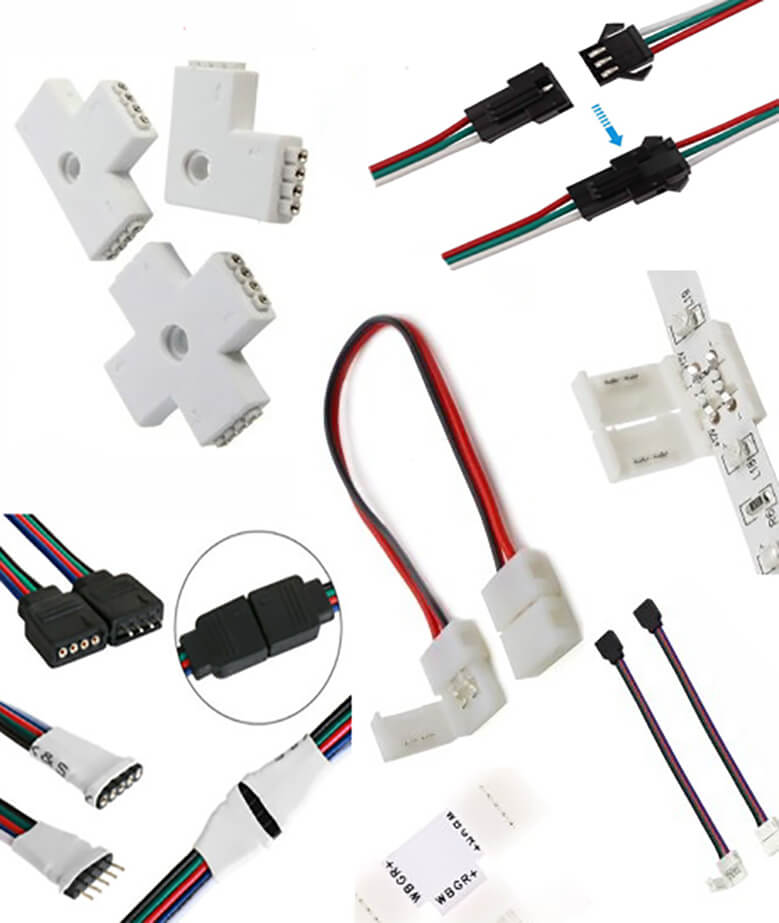

Connector

Myledy provides its consumers with wide range of led strip connectors

Step 4. Other Customize Features

Confirm the Product label

Myledy allows its clients to customize their strip order further by printing the client's product label on the strip or packaging bag.

Confirm the Packaging

Another feature Myledy clients enjoy is customization in packaging. Depending on the reel length and LED type, Myledy provides you a wide variety of packaging options.

Confirm Certificates requirement

Different areas will require different certificates, such as CE, TUV, UL, LM80 etc. Confirm the certificates you need, and then we can provide them accordingly.

Step 5. Confirm Final order & Proceed Mass Production

After confirming the custom features, LED channels, and adapted accessories, the customized light strip order is finalized to the engineering and production team for development processes.

The production team releases orders for the required raw materials based on the order requirements and then proceed the mass production

5.1 Printed Circuit Board Design

The production begins the project by designing the PCB for LED strip lighting. For the best quality results, Myledy uses double-sided PCBs only.

The multi-layer PCBs are better in terms of connectivity and flexibility as they have a layer of conductive metal on both sides of the board.

5.2 Trial Production and Testing

Next step is to prepare a trial custom order and run tests on it. That helps the production team overcome potential issues that might arise in the future.

Myledy prioritizes its products’ quality, which is why our custom orders undergo rigorous testing procedures and quality checks.

- LED Sorting – This test sorts LEDs based on their types and guarantees the consistency of light quality. All LEDs that do not meet the MacAdam ellipse criteria are removed from the production.

- Life Test – All LED strips need to pass through eight hours of life testing to ensure the LED’s life in using.

- QC Inspection – A manual one by the product inspection team, which removes any defective piece before forwarding the final product to the packaging team.

5.3 Mass Production and Delivery

Once the trial production has passed the comprehensive quality inspection, and the strip meets all the customer’s requirements, we’ll move on to mass production in our facilities.

We have highly optimized supply chain departments for timely delivery, ensuring the logistics of operations run smoothly and comply with all the product safety rules.

After-sales service

Hope the guide clarifies the process of ordering a customized strip from Myledy and helps you in making the best choice for your lighting projects.

We will take feedback from our customers to improve our processes further and take proud in providing full customer support post-sales and assistance to our customers. Myledy will make sure they are fully satisfied with the final product.

Promote Your Project with Myledy

1)Free Project Consultation

Confidentially share the details of your project with one of our experienced lighting design consultants who’ll help you determine how best to tackle your vision.

2) Prototyping & Pricing

Our R&D team will help design a prototype of the custom lighting solution needed to make your vision a reality and provide you with a price quote for moving forward.

3) Samples and Product Testing

Once the sample is received, we’ll test the prototype extensively to ensure that it meets your exact specifications and matches the performance characteristics required to make your project a success.

4) Precise Production

After rigorous testing to ensure that we’ve created the perfect solution for you, we’ll proceed with production—manufacturing it under strict quality control standards, so that it’s guaranteed to perform beautifully.

5) Prompt Delivery

After finishing production and completing additional testing to ensure your product’s performance, we’ll ship your lighting solution direct to you within 6-8 weeks of your original order date. All products come backed with a 7-15-year warranty.