Flexible printed circuit boards (FPCBs) are highly innovative electronic devices. They are compact, flexible, and efficient. Having the proper know-how ensures a successful lighting project. No matter what type of lighting task you’re working on, there are bound to be LED strip options to help you out.

1. What is an FPCB?

An FPCB (flexible printed circuit board) is a unique type of electrical circuit. As its name suggests, it is flexible. You can bend and shape them into your desired form.

FPCBs are composed of a thin film or foil made of polyester acting as the substrate material. They are lightweight and heat-resistant, ideal for providing the interconnections in a circuit.

FPCBs have many applications, from automobiles and aviation to consumer electronics and LEDs. Due to their flexibility, their application continues to increase.

2. What Is Its Role in LED Strips?

LED strips are essentially interconnected circuit boards. SMD LEDs and other components mount onto the flexible circuit boards using Surface Mount Technology (SMT). In other words, FPCBs act as the substrate where manufacturers mount the LED chips.

Apart from acting as its structure, another main function of circuit boards is Heat dissipation.

3. Structure and Materials

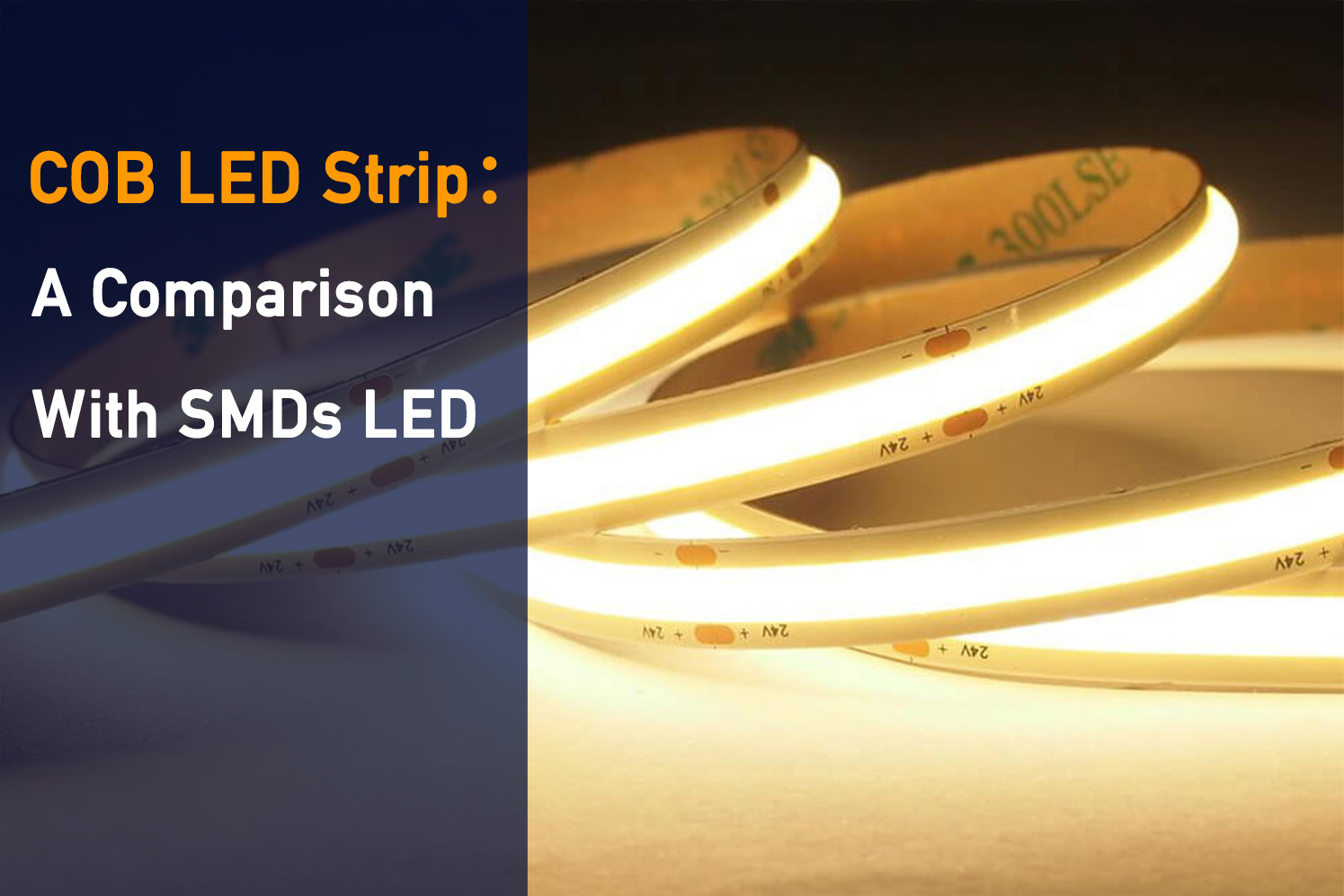

Flexible electronics are malleable, making them ideal for LED strip lights. 5 meter reels are the most common flexible substrate setup for LED strips.

A material called polyimide typically makes up the substrate. Polyimides are durable and heat-resistant.

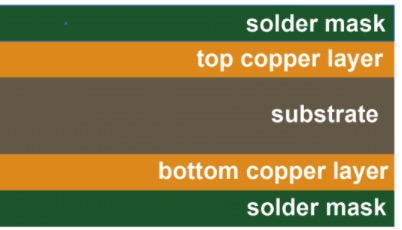

3.1 Single Layer PCB

Single-layer boards consist of a substrate layer and a conductive layer. A solder mask and silkscreen protect these layers. It doesn’t have circuits on its backside.

Single-layer boards consist of a substrate layer and a conductive layer. A solder mask and silkscreen protect these layers. It doesn’t have circuits on its backside.

They have a thin structure, being only around 1-oz in thickness. You’ll feel remarkably lightweight when holding them.

3.2 Double Layer PCB

Compared to a single-layer PCB, the double-layer PCB has two copper layers that makes it thicker and heavier, as it has a conductive layer on both sides.

They’re also more durable as the circuit board can withstand higher currents, and the heat dissipation is better.

In current lighting market, we can find that both single-layer PCB and double-layer PCB have been used for LED strip lights strips. Once you tear off the adhesive tape on the back of the LED strip, you can clearly see the difference between these two kinds of PCBs.

Some manufacturers of led strip light choose single-layer PCB to save the cost. Although the double-layer PCB is more expensive, the LED tapes made by it have higher lumens and better heat dissipation to significantly improve its stability and longer life. It is a necessary choice for the LED strips used in your “done-then-forget” lighting project.

4. Copper Weight

Circuit board thickness is measured in copper ounces (oz.). It is the amount of copper (in ounces) needed to attain a thickness of over one sq.

When it comes to electronic circuits, the copper choice is critical. Though a standard regulates the copper quality applied to electronic circuits, they still vary in thickness.

The copper thickness should be considered when shopping for an LED strip. If you intend to get high-powered ones, you’re going to need thicker copper 2-oz or 3-oz.

LED strips with higher copper thickness has the following advantages:

- Higher electricity flow throughout the LED strip circuit

- Lower electrical resistance

- Faster heat dissipation

- Voltage drops are less likely to happen.

- Better overall performance

5. Heat Dissipation

Circuit boards conduct electricity which means they’re going to generate heat. The heat dissipation performance of the FPCB is relatively poor.

Because the PCB board is thin, it won’t be able to dissipate heat efficiently.

There are several ways to overcome the heat dissipation problem:

- Use FR-4 or MCPCB instead. They can greatly improve thermal performance, but they don’t have flexibility features

- Use an LED channel as a heat sink. In addition, it can also protect the light strip and enhance the light effect

- Use a thicker or wider PCB. This means that they can dissipate heat more efficiently.

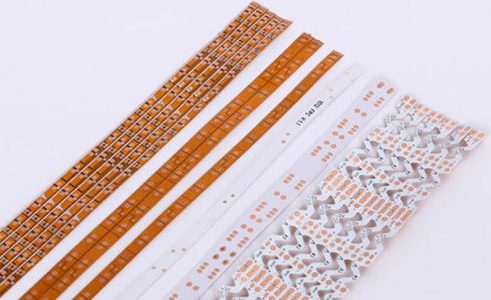

6. PCB Width

Flexible PCBs used for LED strips come in varying widths. The one you’ll choose will depend entirely on your lighting project. FPCB widths differ widely, ranging from 4mm (ultra-slim) to more than 15mm.

Let’s have a look at the applications for each of the typical LED circuit board widths.

Ultra Slim (4 - 6 mm)

These ultra-thin circuit boards are highly flexible, easily going through narrow spaces. Despite their thin structure, these boards produce decent brightness and color rendering index.

Regular (8 - 10 mm)

The most common circuit board width for LED strip lights ranges between 8 - 10mm. This size range is suitable for most lighting projects. You can use them almost anywhere, from everyday use to high-end lighting designs.

High-Power and RGB, RGBW (12mm)

12mm flexible PCBs are able to make high-powered or RGB, RGBW LED tape. The thicker substrate allows the LED to produce high brightness while maintaining low operating temperatures. You can apply these LED strips to projects that require high performance, such as outdoor decorative lighting.

15mm or Wider

LED strips used for direct lighting typically mount on 15mm-wide flexible PCBs. Because of their broader structure, these FPCBs produce the brightest illumination. The intensity is perfect for any residential, commercial, and industrial applications.

S shape FPCB

In order to meet the requirements of some special linear light projects, we have designed an S-shaped FPCB. It can not only bend back-forth, also bend up and down to achieve maximum flexibility to meet the installation routes of various LED strip light.

7. PCB Design Support

If you have a complex lighting project, Myledy engineering team can help you design custom-tailored circuit boards. PCB design support lets you customize your existing circuits to fit your specific project. It’s perfect for when you need unique designs, brightness output, and accessories.

PCB design support is beneficial when you need your PCBs to meet certain specifications.

Conclusion

Flexible electronic technology has seen tremendous growth in recent years. Because of their flexibility and efficiency, many industries have already adopted them.

We hope that all your questions regarding FPCBs are clarified in this article. If you have any more inquiries, don’t hesitate to contact our team.

Myledy has over 17 years of experience and knowledge under its belt. We are committed to upholding ourselves to the highest standards by providing superior LED strip light products.

If you need a solution for your lighting project, get in touch with Myledy today.