Myledy LED Neon Flex

- Outstanding Quality and Competitive Price

- Top-Ranking R&D Team to Support Your OEM Project

- Amazing Delivery Time

- Unimpeded and Clear Communication

- Warm After-sales Service

Founded in 2003, as the leading manufacturer of LED strip lights in China, Myledy also focuses on the development and production of top-grade LED neon lights. Our LED neon uses state-of-the-art LED tape inside and top-quality silicone materials to ensure the outstanding lighting performance and a super long use lifetime.

With its excellent R&D team, Myledy has not only developed a variety of LED neon lights for bulk requirements but also can provide you with professional customization services.

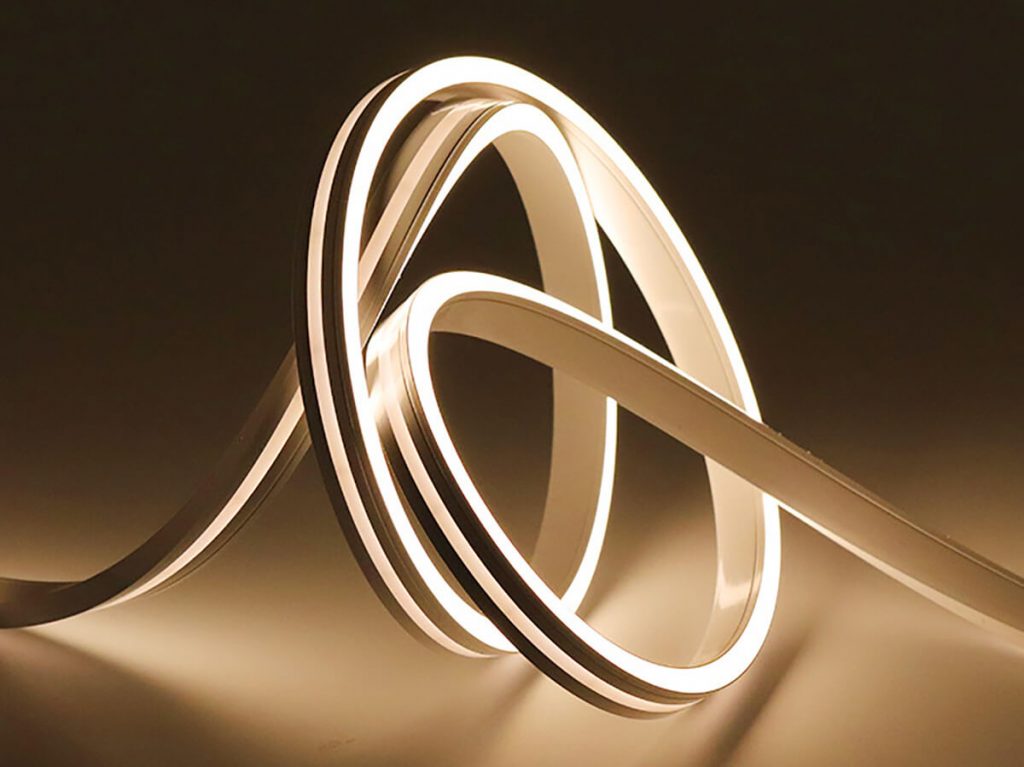

Gallery Of myledy LED neon lights

Based on durability, safety, and soft lighting, Neon LED flex lighting is a versatile and flexible solution for various applications. Comprising long, bendable neon tubing, it allows for customized designs and can be used for static or animated displays. Myledy can offer an extensive portfolio of LED neon flex lights in a variety of sizes, IP ratings, color temperatures, lumen outputs and LED types, providing the perfect energy-saving option for your various projects.

- Valtage: DC 12V, DC 24V and DC 48V;

- Multi-colors: nature white, dual white, RGB, RGBW, DMX RGB/RGBW;

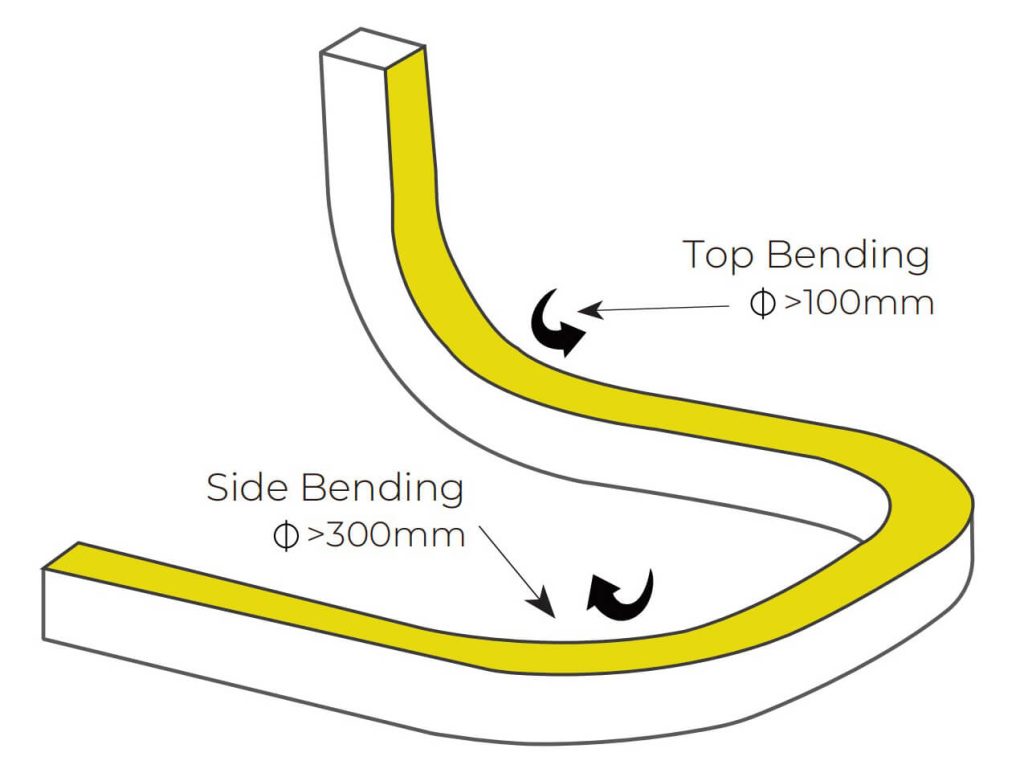

- Bending types: side bending, top bending, 3D bending, 360° lighting;

- IP grate: IP65, IP67, and IP68;

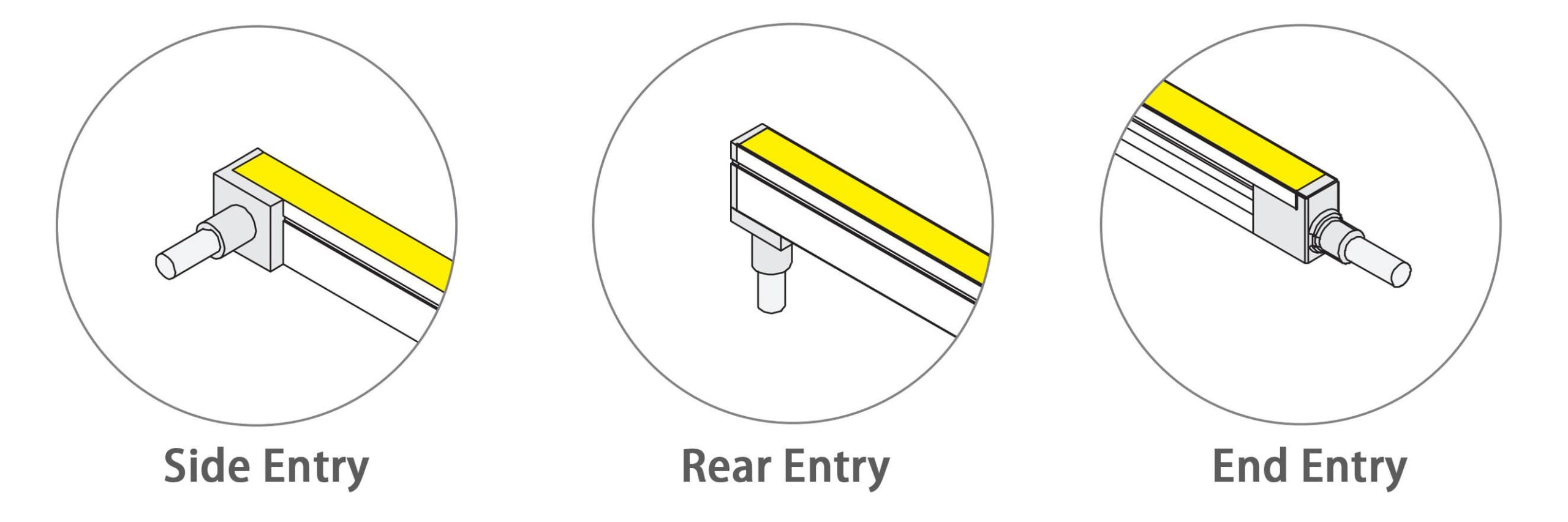

- Cable outlet: rear outlet, straight outlet, side outlet.

Here explore Myledy Neon flex range for an easy-to-use and eye-catching lighting solution.

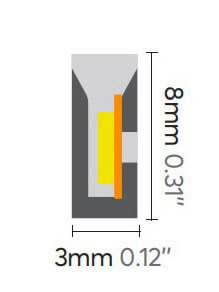

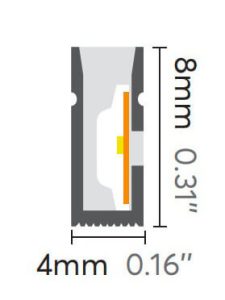

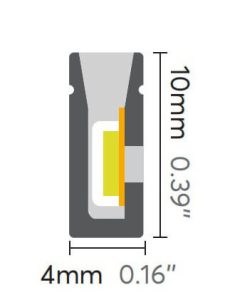

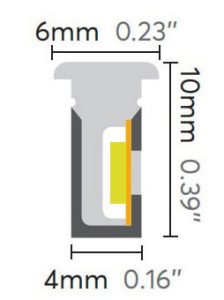

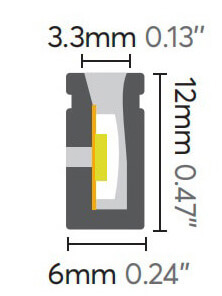

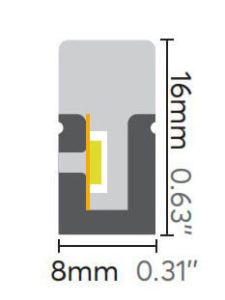

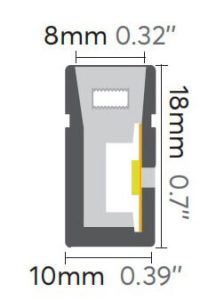

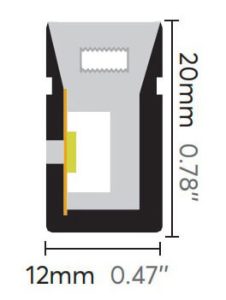

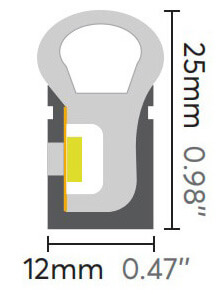

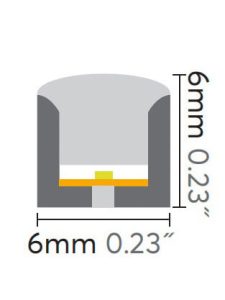

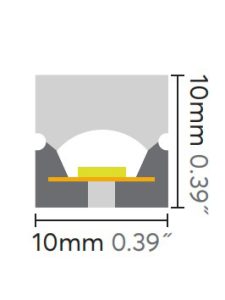

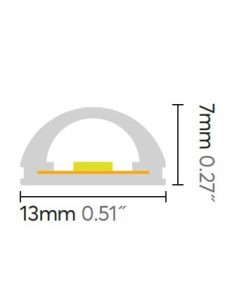

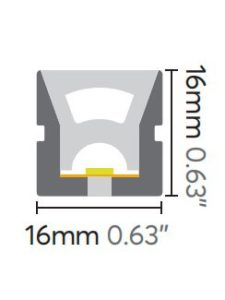

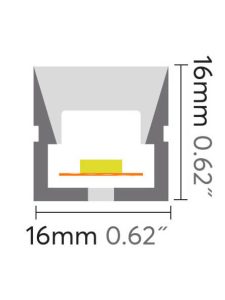

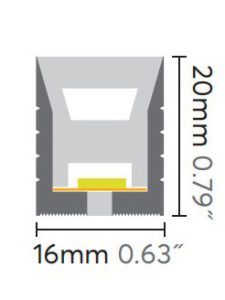

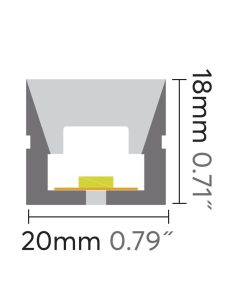

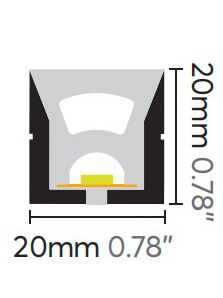

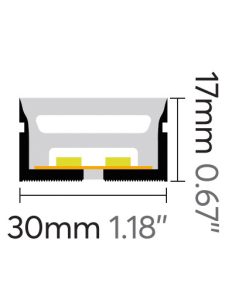

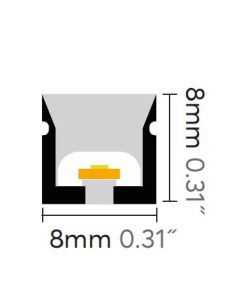

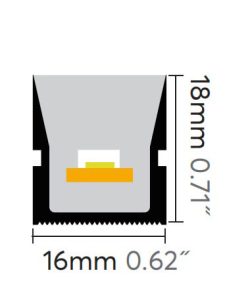

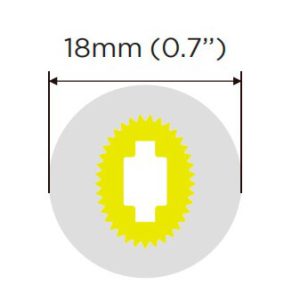

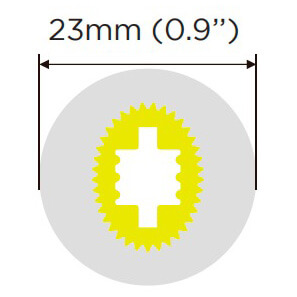

Dimensions chart of Myledy LED Neon Lights:

different series of Myledy LED Neon Lights: LED Neon Lights:

know more About Myledy LED Neon

NEON LED flex lighting is a versatile and flexible solution for various applications, including neon signs and automotive lighting. Comprising long, bendable neon tubing, it allows for customized designs and can be used for static or animated displays. Available in different sizes and powered by DC voltage, our LED neon lights offer energy-efficient options for diverse projects, with variations like side bending, top bending, 3D bending, 360 round, IP68, and DMX RGB/RGBW neon flex.

Whether it’s signage or a decoration piece, neon LED strip lights are built to illuminate the whole room with its bright, funky colors and clear light. Explore our range for an easy-to-use and eye-catching lighting solution.

1. What is LED Neon Flex?

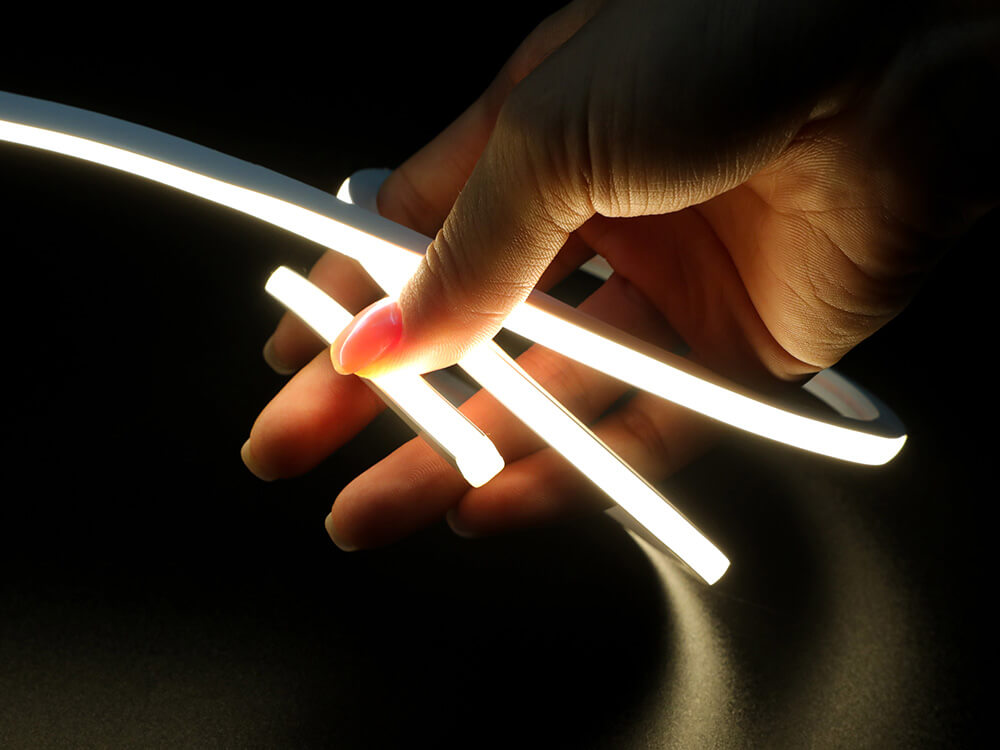

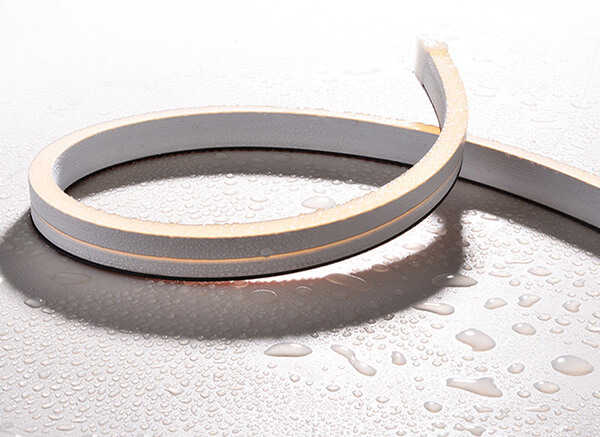

Neon LED strip lights – the flexible linear lights, are the most efficient form of LED lighting that you can use in residential, commercial, and industrial areas. This strip is a flexible LED tube, enclosed in silicone and consists of a cluster of LEDs installed on a PCB strip.

Simply put, neon lights are composed of three parts:

- LED light strip + silicone sheath + connecting wire

Neon lights are made of a two-color or three-color silicone integrated extrusion molding process.

Compared with LED strip lights, they have better waterproof properties – the protection level is up to IP67/IP68, and more beautiful linear lighting to achieve dot-free. It also has Durability characteristics such as acid and alkali resistance, corrosion resistance, and fire resistance.

Why use LED neon light?

Every neon flex LED light comes with dotted lines present after every 1 meter along the solder pads. You can cut them to achieve the desired length.

Once you install these Neon LED flex, you don’t need to do anything else as they require little to no maintenance.

These neon LED strips convert electrical power into visible energy in a more efficient manner. Without having to compromise on the LED light output, you can reduce your energy costs.

All neon led strips are designed with IP67 waterproof grade. Available for outdoor use.

Myledy neon LED strip lights are extremely flexible and feature a minimum bending diameter of 6cm.

Neon lights can replace the aluminum trough installation and protection required by LED light strips. It is more widely used in indoor and outdoor decoration, building outline, urban night scene lighting and other applications.

Highly flexible, Uniform and beautiful light output, making LED Neon Light a variety of shapes and be widely used. Here are some ways you can utilize this flexible neon light for:

- An accent, or drawl lighting in your living area

- Task lighting in your office

- Creating your retail display signages

- Ambient lighting inside your RV or around your RV’s awning

2. the features of myledy LED neon flex.

Whether it’s signage or a decoration piece, neon LED strip lights are built to illuminate the whole room with its bright, funky colors and clear light. Even though neon lights got trendy a while ago, there are different variants available in the market.

Myledy can offer a broad portfolio of LED lights strips available in various sizes, IP ratings, color temperatures, lumen outputs, and LED types. The neon LED deliver a uniform lighting so that you can have the perfect ambiance. Here are some other benefits you must know about neon light strips:

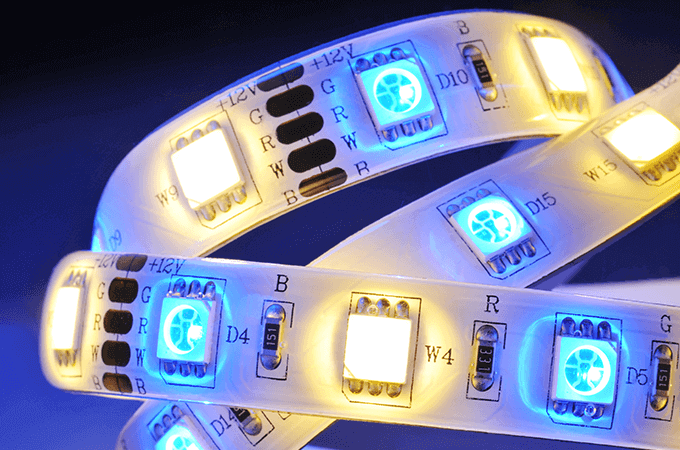

Qualified Myledy LED tape inside

As the quality core of neon lights, myledy’s neon lights use our own LED tapes which are produced with top materials and under strict quality control to ensure the quality of neon lights.

top grade silicone skin

Myledy uses the best high-transparency silicone to ensure high light efficiency and uniformity of light.

kinds of cable entry

Different outlet methods can meet various installation requirements.

Different outlet methods can meet various installation requirements.

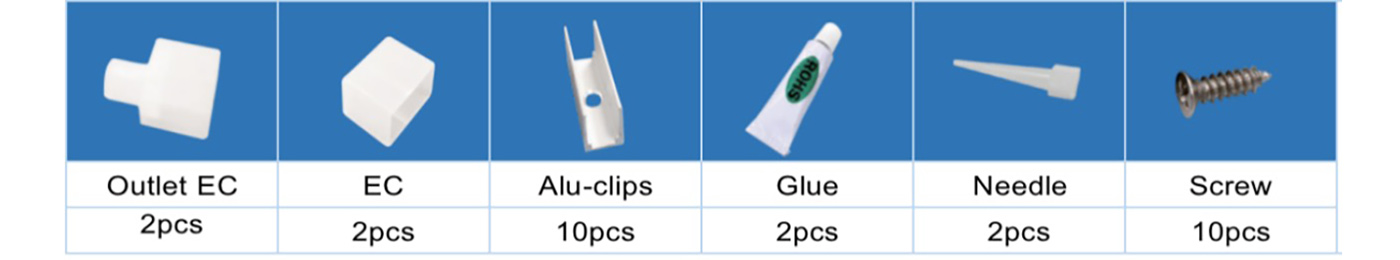

Complete accessories

Each roll of neon (5m) comes with a standard accessories package:

We also provide a wide selection of mounting profiles, bendable mounting track and various end caps.

Full Category

Explore a diverse range of LED Neon Flex categories, saving you time and effort in finding various products.

Flexible customer customization

Our professional R&D team is ready to assist with your specific project requirements. We specialize in manufacturing and customizing services.

3. How is myledy LED neon light produced?

Firstly, we commence the process by blending fumed silicone glue with additives. Once mixed, the silicone is prepared for extrusion.

Subsequently, the LED strip and silicone undergo the extrusion machine, effectively enveloping the LED strip with silicone. The Neon LED then progresses through the vulcanizing oven, where, post-vulcanization, it is pulled out by a conveyor.

Thirdly, we proceed to solder the wires and craft the end cap to the customer’s specifications.

Fourthly, An essential aging test ensues to ensure the optimal functionality of all Neon LED flex components.

Finally, our QC department meticulously conducts visual inspections before the final packaging is carried out.

This comprehensive process guarantees the quality and performance of our LED products.

How to customize your LED neon flex?

Addressing your unique LED neon needs for special events, architectural projects, and other bespoke lighting requirements. Customization options include:

- Based on normal neon type — It’s very easy to customize the color, length, and cable outlet for your special projects.

- Customization of new neon flex styles — Our professional R&D experts can design new neon lights according to customer descriptions and then provide samples meanwhile ensuring the exclusive supply.

Dimension-

You can design the width, height, and thickness to ensure a tailored solution to meet the specific requirements of each application.

Shapes-

Our products are can be customized into various shapes, including slim, flat, square, tri-view, round 360-degree, 3D bend, and mini neon.

IP Rating-

Higher IP rating equals better waterproofing for LED neon lights; IP68 is the highest wet rating. Customization available based on your requirements.

Custom Length-

Standard neon lights is 5 meters, but we can produce other lengths to match your project's requirements.

Color Temperature-

Color temperature directly influences the environment's feel. Utilize our light customization service to choose the right CCT for your neon lights.

Power consumption-

Power consumption can be adjusted to suit various applications, such as accent lighting, under-cabinet illumination, or others.

Cable entry and Bend type-

To prevent design errors, we provide clients with freedom to choose cabel entry and bend designs.

Why choose MYLEDY LED Tape Light?

Top Quality Neon Lights

- LED Chip – Generally, MYLEDY Led strips are using Epistar LED chips. We can also take other brand chips according to customers’ requirements such as Cree Samsung Philips chips etc. High quality LED strip lights are myledy’s consistent pursuit.

- PCB Board – Myledy uses at least 2 oz 100% pure copper pcb plates, some are 3 ounces and 4 ounces for better heat dissipation. Our PCB boards are purchased from well-known PCB producers that can meet the CE, RoHS, UL etc requirements and ensure excellent quality.

- Top Silicone Skin – As an important component of neon lights, the quality of silicone skin will affect the brightness and uniformity of neon light. Myledy has always used the top quality silicone to produce the most elegant and durable neon lights.

Color Consistency

Color consistency is particularly important for Myledy focusing on high quality projects. Apart from ensuring color consistency for one order, we will record each batch BIN number (≤2 Step, +/-50K) ensuring that the following orders can be as consistent as possible before orders. To make sure guests projects display perfect lighting effect.

Extreme Strict Quality Control

Myledy automated production equipment allows inspection of each step of production, to ensure zero failure rate and the delivery time within 7-15 working days. Every stage of production is inspected by trained QC workers. All strip lights will undergo a 4-8 hours aging test to ensure 50000hours lifespan.

Flexible MOQ & Competitive Price

Myledy’s regular MOQ is 200m, but flexible MOQ customized lighting projects are also available. Opt for MYLEDY as your LED Neon Flex supplier and enjoy competitive wholesale prices when buying in bulk.

Experienced R&D Teams and Sales Team

Our experienced R&D team enable myledy to innovate continuously, while satisfy customer requirements for OEM projects. Our professional sales-mate reply your questions at first time.

Intimate after-sales service

All Myledy LED strip lights provide 5-year after-sales service. Our professional and considerate service will make your lighting project worry-free forever.

For your “done-and-forget” LED lighting projects

What

We can do

for you?

Free Samples

Myledy can provide Free samples of LED strip for customers to better decide what products are needed for his projects.

LOGO Printing

Customized LOGO, date, batch number etc. can be printed on LED strip PCB.

Special Accessories

Relevant cables, connectors, LED profiles, power and other special accessories are available for your projects.

Customized Length & Color

Myledy is proficient in color consistency of led strip lights, we keep one bin and make customized length of LED tape for your projects.

Certificates & Testing Reports

Myledy LED Strip lights have CE, UL, RoHS certificates, and we can profile LM80, IES, Integrating sphere test reports

Prompt Delivery & Economic Freight

7~8 days for regular IP20 LED Strip; 15 days for IP62~IP65 LED tapes; 14~18 days for LED neon flex. Shipment by sea or air is based on your requirement.